cavity;

Ж – dimension

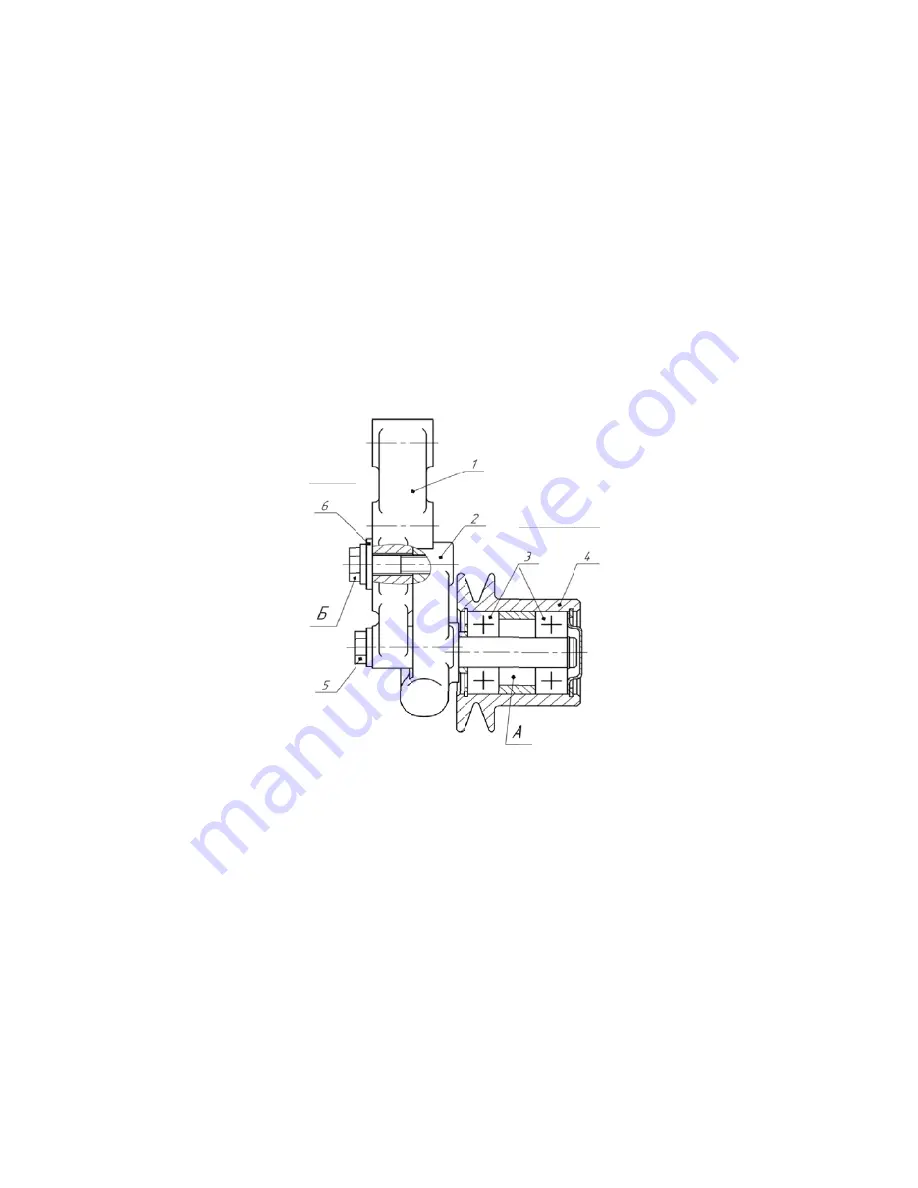

4.13 Tension machine 236-1307155-

А

4.13.1 Assembling bearings 3 (picture 4.12) should be lubricated with the grease Litol-24, and

cavity А of the pulley between the bearings should be filled with this grease for 3/4 of the volume.

4.13.2 B

earings 3 should be pressed with the sides without sealing to the cavity А.

4.13.3 After the assembling pulley 4 should rotate free without constraints at the lever pin 2

from the manual effort.

4.13.4 Bolts 5 of the support fasteners 1 to the lever 2 are finally tightened at the engine after

the adjusting of the belt tension.

4.13.5 At the bolt B additional flat washer 6 with the increased external diameter should be

installed.

Picture 4.12 – Tension machine 236-1307155-

А

1 – tensions machine support 236-1307206; 2 – lever with the pin 236-1307304-

А;

2 –

bearings 20803 К3; 4 – tension machine pulley 7511.1307180; 5 – bolt 201682-П29;

6 – washer 312696-

П29; A – cavity

4.14 Fan drive

236НЕ-1308007-Д and 236НЕ-1308011-И

4.14.1. Parts assembling of the position 19, 20 or 21 should be performed in

accordance with the GOST 3325-85. Transmission of the thrust force through the rollers is

not permitted.

4.14.2. Before the assembling lead in part of the thread of the parts of the position 12 and

15 should be lubricated with sealant UG-

9 ТU 2257-407-00208947-2004 or UG-10 ТU 2257-

408-00208947-

2004 or Anakrol 202 ТU 2242-003-50686066-2003.

Содержание ???-236

Страница 25: ...26...

Страница 26: ...27 2...

Страница 40: ......

Страница 41: ......

Страница 53: ......

Страница 56: ......

Страница 59: ......

Страница 64: ...236 238 1003014 3 236 238 1003014 4 236 238 1003014...

Страница 65: ......

Страница 70: ......

Страница 73: ......

Страница 81: ......

Страница 85: ......

Страница 92: ......

Страница 95: ......

Страница 101: ......

Страница 113: ......

Страница 119: ......

Страница 122: ......

Страница 125: ......

Страница 128: ......

Страница 142: ......

Страница 144: ......

Страница 150: ......

Страница 155: ......

Страница 158: ......

Страница 160: ......

Страница 165: ......

Страница 178: ...4 A induction manifold Thread stripping no more than one thread 10 6 20 1 5 6 To reject To calibrate the thread...

Страница 193: ...N u M a r Method defect detection and Dimension and parameter mm...

Страница 201: ...4 Thread stripping M16 1 5 6H no more than two threads Inspection To calibrate the thread...