For Service Engineer

Service Information

SI1604009E-002= S20, S10, M20, M10 and D10 installation procedures

26/34

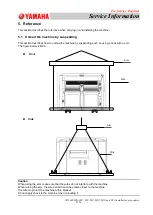

4.4 Confirm the PCB transfer

Set a board on the conveyor and slide it from the upstream machine manually

and confirm that the PCB slides smoothly between the machines.

Adjust the position with the reference machine

Check that the levelness of the machine falls within the specification.

Check that the reference conveyors of the reference machine and the adjacent machine are

properly aligned.

Check that the position of the machine being installed is not shifted in the R-direction.

(The machine is aligned with the reference machine.)

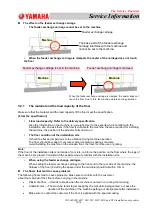

Adjust the height with the reference machine

Check that the height at the connecting part of the conveyors is the same.

Place a jig for aligning the production line or a test board each on the conveyors at the

connecting part of the reference machine and the adjacent machine, and check if the

height of the conveyors is the same.

Adjustment when the transfer is not smooth and there is a gap between the machines

Move the machine, turn the adjuster bolt and etc., and perform the adjustment.

Note:

When sliding the board, push it against the reference conveyor and then the movable conveyor to check if

the board can be transferred smoothly on the both side.

Make sure that there is no

height difference between the

boards.

Keep the height difference

about 0 to 0.5mm

.

The clearance between the conveyors:

5mm or less

The already

installed

reference

machine

The adjacent machine

(Being installed)

There should be no clearance

between the boards.

The adjacent

machine (Being

installed)

The already

installed reference

machine

The already

installed reference

machine

The adjacent

machine (Being

installed)

Steel ruler

There should be no clearance between

the scale and the conveyors.

Check with a steel ruler

Check with PCB