For Service Engineer

Service Information

SI1604009E-002= S20, S10, M20, M10 and D10 installation procedures

17/34

3.7.5

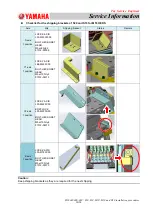

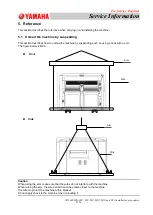

Position the machine

After roughly positioning and the leveling temporarily, raise the toe of the jack and raise the machine.

Step 1. Raise the adjuster bolt and support the machine by a jack.

Step 2. Raise the machine by a jack while confirming the level vial.

Pay attention to the conveyor height of the reference machine and set the machine slightly lower.

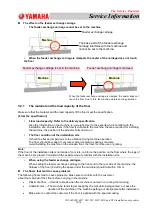

Step 3. Align the machine positions.

Push the machine in order to align the reference machine and the conveyor.

The machine can be moved easily while a jack is raised. Make sure not to push the machine

excessively.

When pushing the machine, push the lower side of the machine. Install the machine to the position

where the space between machines is less than 5mm.

(If pushing the upper side of the machine, it will shake and may not be moved.)

Step 4. Align the transfer height.

Raise each jack to the same height while confirming the level vial.

Step 5. Place the rubber plate under the adjuster bolt.

Move the rubber plate enclosed the machine so that the center of the adjuster bolt is placed on the

center of the rubber plate.

Step 6. After completing the leveling and the positioning adjustment by raising a jack, lightly

foot the adjuster bolt on the floor.

Extend the adjuster bolt strongly little by little while confirming the level vial so that the 4 points will

be the same level.