For Service Engineer

Service Information

SI1604009E-002= S20, S10, M20, M10 and D10 installation procedures

11/34

3.5 Preparation before marking

When installing several machines, it is required to install the reference side conveyor correctly

on the marking line and the PCB to be transferred flow smoothly from the top machine to the

last machine.

It is also required to narrow the space between machines as much as possible and reduce

the transferring loss.

This is generally called

“marking”.

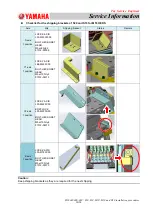

Required tools

Level vial

: At least 2 pcs

PCB for marking

: At least 2 pcs

Dedicated jig PCB

: (Required when connecting our machine to other manufacturer

machines)

Steel ruler

: 1m or 60cm steel ruler (If not having them, approx. 3m metal tape

measure can be substitution.)

46mm wrench

: At least 2

30mm wrench

: Used for S20 and M20 supporting adjuster bolts

Sliding paper

: At least 8 sheets

Acrylic plates

: At least 8 plates

Hydraulic toe jack

: 4 sets

Mini jack

: 1 set (it is used depending on the situation.)

Plumb bob

: Required when marking with ink.

Manometer

General tools

The accuracy of a desirable level vial (mm/1m) is 0.02

or less.

If the level vial is equipped with the function of

adjusting the height, a shim is not required for

confirming the torsion of the X-beam.

See

“ for

further information.