23

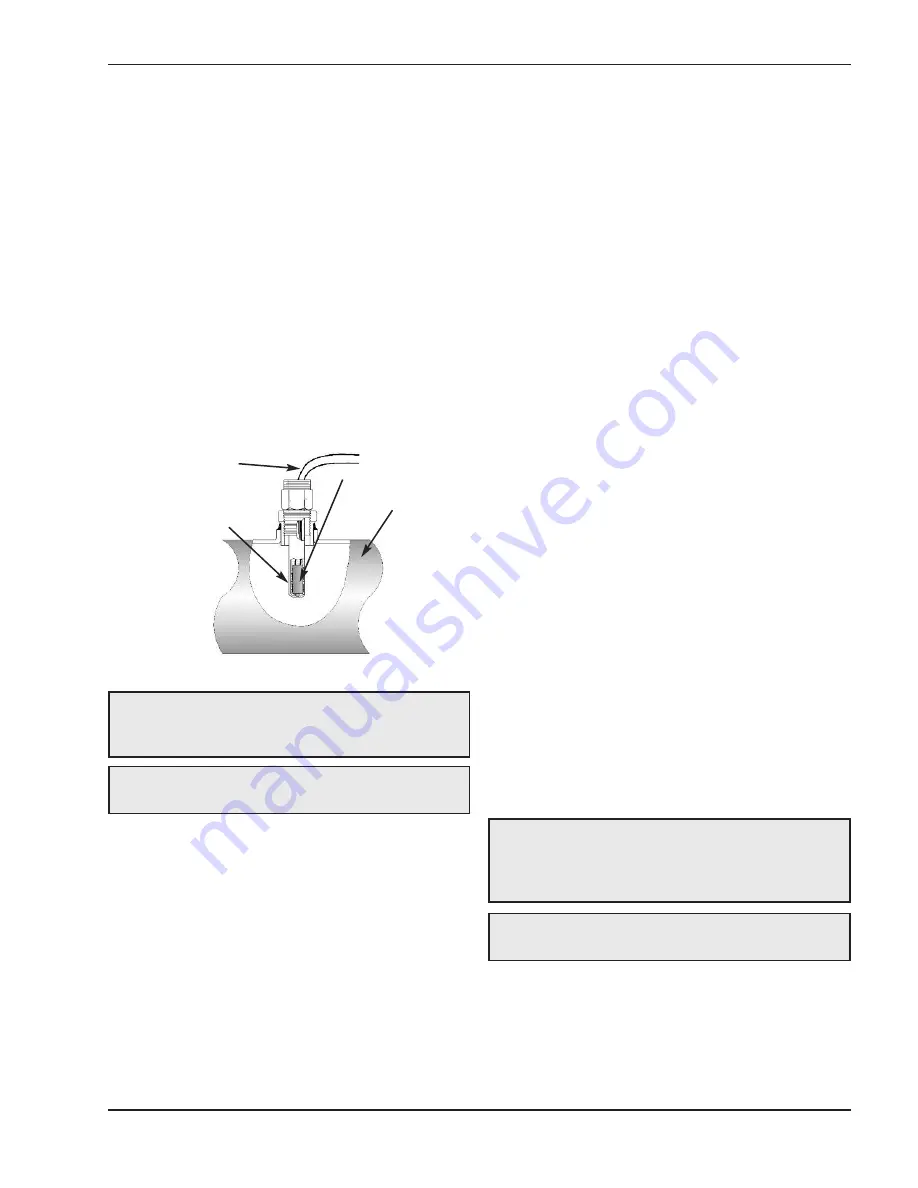

Heating Sensor Installation

1. Only use the System sensor provided with the

unit.

2. The sensor wires can be extended up to 500 ft

using a shielded 2-conductor cable.

3. Do not run sensor wires in conduit with line voltage

wiring.

4. Install a 3/8” ID 1/2 NPT immersion well.

5. If installing the system sensor on the supply, insert

the sensor in a well with heat paste no more than

5 ft past the boiler loop outlet on the common sup-

ply header, but before any major takeoffs. The

sensor must be located where it sees the output of

all the boiler stages. If a boiler is piped so that the

sensor does not see its output. the VERSA IC

®

will

not sequence the boilers correctly.

Wiring the Outdoor Sensor

1. There is no connection required if an outdoor sen-

sor is not used in this installation.

2. If using an Outdoor Sensor, connect the sensor

wires to the terminals marked OUTDOOR SEN-

SOR (see wiring diagram). Caution should be

used to ensure neither of these terminals

becomes connected to ground.

3. Use a minimum 18 AWG wire for runs of up to 150

feet.

4. Mount the outdoor sensor on an exterior surface of

the building, preferably on the north side in an

area that will not be affected by direct sunlight and

that will be exposed to varying weather conditions.

Wiring the Indirect Sensor

1. There is no indirect sensor connection required if

an indirect water heater is not used in the installa-

tion.

2. When the Indirect DHW call for heat is active, the

PIM communicates this to the VERSA. The

VERSA calculates the optimal operation and

sends the firing rate and pump output requests to

the PIM so it can activate the Indirect DHW pump

and Boiler pump if needed. If an optional Indirect

DHW sensor is connected to J2-1 and J2-2 the

PIM will pass this signal to the VERSA. This allows

the VERSA to optimize the Indirect DHW demand

to maintain the Indirect DHW setpoint. The Indirect

DHW thermostat switch closure is not required

when using the Indirect DHW sensor. If a VERSA

is not present the PIM shall activate the Indirect

DHW pump whenever the Indirect DHW call is

active. The Boiler pump may also be activated

based on the Indirect DHW piping configuration

setting.

3. Connect the indirect tank sensor to the terminals

marked INDIRECT DHW SENSOR (see wiring

diagram). Caution should be used to ensure nei-

ther of these terminals becomes connected to

ground. When using an indirect DHW sensor to

control tank temperature, contact closure is

required across the indirect DHW override con-

nections. To ensure proper operation during “limp

along” mode set PIM operator dial to be equal to

DHW Target temperature condition from occurring.

See VERSA IC manual, catalog 5000.72.

Wiring the Optional 0–10 Volt

Building Control Signal

1. A signal from an energy management system may

NOTE:

Alternately, a thermostat contact closure can

be used in lieu of the sensor for indirect operation.

Connect the thermostat to the terminals marked IND

REMOTE THERMOSTAT.

NOTE:

If the System Sensor (S3) can not sense the

correct water temperature, the VERSA IC

®

will not

provide comfortable heat levels.

WARNING:

Use only the System and Outdoor Air

sensors included with the control.

CAUTION:

Sensor and control wiring must

NOT

be

run in conduit or chases with line voltage.

Fig. 19: System Sensor (S3)

Heating

System

Sensor

Immersion Well

3/8” ID 1/2 NPT

Common

Supply Pipe

Sensor

Probe

Содержание 300A-850A

Страница 46: ...46 WIRING DIAGRAM...

Страница 62: ...62...

Страница 63: ...63...

Страница 64: ...64 www raypak com Raypak Inc 2151 Eastman Avenue Oxnard CA 93030 805 278 5300 Fax 805 278 5468 Litho in U S A...