Manual 26727

VariStroke-I (VS-I) Electro-hydraulic Actuator

Woodward

18

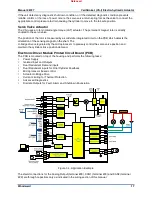

The power supply system performs the EMI filtering on the (18 to 32) V (dc) input voltage, generates

controlled voltages for several electronics sub-systems and is monitored for proper operation. If input

voltage or internal power systems are detected outside of allowable operating ranges, a diagnostic alarm

will be enunciated.

Calibration and configuration of alarms and shut down and redundancy operation are configurable via the

PC Service Tool.

The primary demand and redundant demand / feedback input signals are designed for a (4 to 20) mA

control signal. Each input signal is EMC protected.

Discrete outputs are provided for alarm and shut down enunciation. An internal LED also is illuminated

when a fault condition is detected. Cover needs to be removed to see this LED. The configurable discrete

output can be customized to output a variety of enunciations using the PC Service Tool. All of the discrete

outputs are configurable for normally open or normally closed action using the PC Service Tool.

Cylinder Position Control

The cylinder position controller adjusts the hydraulic power cylinder position to match the feedback signal

to the demand. Monitoring of both the servo position controller and cylinder position controller ensures

accurate tracking.

The position controller regulates a Pulse Width Modulated (PWM) drive signal to the actuator. The drive

current to the actuator is regulated, transiently allowing up to 10 Amps to be provided to move the

actuator at its maximum speed and torque. A steady state current limit becomes active after a period of a

few seconds to protect the actuator and electronics.

VS-I Remote Servo Only Construction

The Remote Servo (Figure 1-5) has the following major components:

1. Rotary Servo Valve

2. PCB (This information is available in the VS-I Integrated and Remote Construction section above

Rotary Servo Valve

The hydraulic servo valve has five ports: Supply, two Control Ports, Over Board Drain (OVBD), and

Drain/Tank. With the hydraulic valve in its middle position, both control ports are blocked. As the valve

rotates, supply pressure is connected to a control port while simultaneously connecting the drain to the

other control port. The combined action of the servo position controller and cylinder position controller

modulate the power cylinder position as necessary to match the input demand. OVBD is permanently

connected to drain and can (optionally) be connected to the OVBD connection on Hydraulic Power

Cylinder to drain any leakage pass the primary rod seal.

A unique function of the software is a periodic, symmetrically opposed impulse (called "Silt Buster") which

flushes silt and debris from the servo valve without causing undue wear. At the interval and amplitude

selected by the user, this function provides a very rapid motion of the hydraulic valve, allowing any silt to

be flushed to the drain passage. This motion is followed immediately by a step of equal amplitude in the

opposite direction. The opposing symmetry of the impulse results in no net change in fluid volume to the

controlled servo valve, and thus does not interrupt the control of the turbine. This unique function provides

a higher degree of stability, reliability, and silt resistance.

If the unit detects any diagnostic shut down condition, or if the detected diagnostic condition prevents

reliable control, or if a loss of power occurs, the servo valve return spring forces the valve to connect the

appropriate control pressure to drain, causing the cylinder to move to the fail-safe position.

Released