Manual 26727

VariStroke-I (VS-I) Electro-hydraulic Actuator

Woodward

12

Chapter 1.

General Information

Introduction

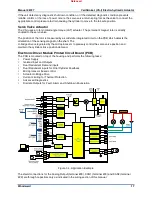

The VariStroke-I is a linear electro-hydraulic actuator that utilizes a double-acting or spring-assist power

cylinder with integrated electronic driver module, servo valve, and redundant MLDTs (Magnetostrictive

Linear Displacement Transducer) – based position feedback sensors to precisely control steam turbine

valves. The actuator’s driver module accepts one or two (redundant) 4–20 mA demand setpoints and

compares these setpoints to the sensed actuator shaft position to accurately control output shaft position.

The actuator’s output shaft position is controlled by a digital controller with an internal rotary servo valve

that ports supply oil to and from its power cylinder piston. This actuator’s digital controller architecture

allows it to perform stable position control during normal conditions, and responds quickly to desired valve

step changes during system or plant transients. The actuator output force is generated only by oil

pressure for double-acting power cylinder. For the spring assist, actuator output force is a combination of

force from hydraulic pressure and spring. Spring assist cylinder is still working as double acting actuator

but it has a spring installed inside the cylinder. Spring can be mounted either on the piston or rod side and

it generates force toward the failsafe position. There are three different spring force categories for each

cylinder diameter, except for 8” and 10” cylinder bores which need four spring force categories to cover

application needs. The springs are rated at about ~1.5%, ~2.5%, ~5.5%, and ~10.5% of stall force at 500-

psi supply pressure.

As a means of protecting the turbine, an internal servo valve-return spring forces the actuator to a failsafe

position to safely close turbine control valves upon any internal unit failure (electrical input power failure,

position sensor failure, processor failure, etc.). Additionally for the spring assist, power cylinder the

actuator spring assists in closing the valve in the event of the loss of oil pressure and helps to maintain

fail safe position.

The VariStroke-I actuator is a product family with many different models available for purchase depending

on the force, stroke, and redundancy required. Servo V45 (flow 212-530l/min) works with 4, 5, 6, 8 and 10

inch actuators. Cylinders are available with standard bore diameters and standard stroke ranges. The

VariStroke’s unique “variable stroke” capability also allows users to customize/set the actuator’s exact

maximum stop position in the field to meet their requirement. The VariStroke-I is available as an

integrated unit, or as a Remote Servo kit where the cylinder can be mounted up to 3 meters (approx.

10 feet) away from the servo. V45 servo is available also as Servo Only option for users who wish to use

their own hydraulic cylinder.

The VariStroke-I is factory and/or field configurable via a computer-based service tool. The actuator’s PCI

Service Tool uses a simple user-friendly format to allow users to easily configure, calibrate, and adjust all

internal functions and response settings. The VariStroke-I also includes a 4–20 mA output channel to

indicate output shaft (control valve) position, and unit alarm and shut down relay outputs for use as unit

health and status indications.

The total installed cost for this fully integrated actuator is low because it has been completely assembled

and tested at the factory. This greatly reduces OEM and end-user fabrication time, testing time, and site

assembly time.

The VariStroke Actuator offers the following benefits to the user in comparison to other electro-hydraulic

actuators:

Released