9

Disturbances during operation and trouble-shooting

46

Translation of the original operation manual

•303_208176_1004_en•ski

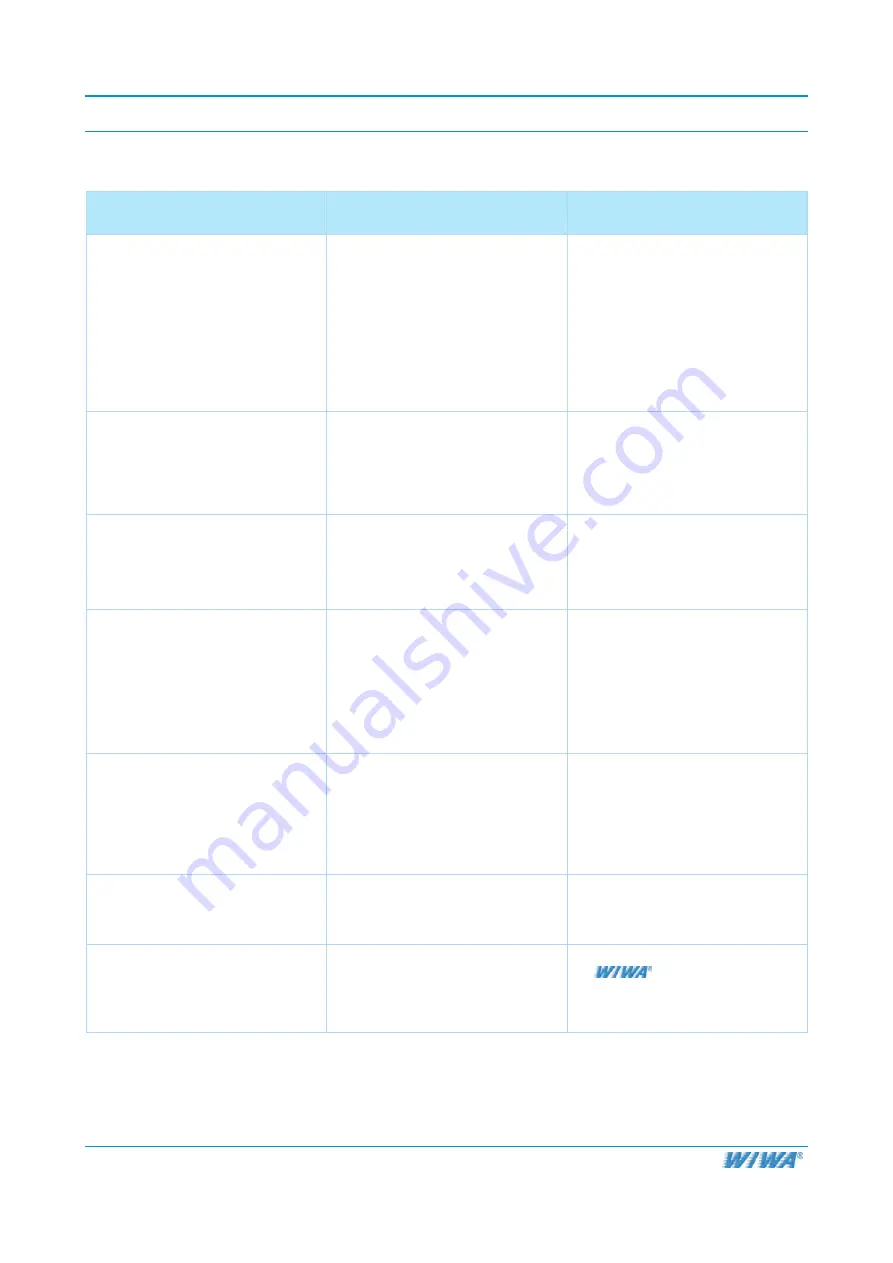

Faults

Probable Causes

Remedies

15. When spraying, the air motor runs

irregularly.

The pressure gauges show a

synchronously swaying material

pressure.

➤

The air supply line is not sufficient.

➤

Cross section of air supply line is

to small

➤

Pressure in the air supply system

is too low.

➤

The air pressure adjusted at the

air maintenance unit is the same

as the pressure of the air supply

system.

➤

Change the compressor.

➤

Enlarge cross section of air supply

system.

➤

Increase air pressure in the air

supply system.

➤

Lower the pressure at the air

maintenance unit.

16. When flushing, there is an in-

creasing pressure at one or both

pressure gauges, although the 2-K

unit is released from pressure and

the „CIRCULATE“ lever/switch is

CLOSED/OFF.

➤

Anti-return valves of mixing block

do not work.

➤

Clean mixing block.

➤

Replace defective balls, valve

seats or tension springs.

17. When turning from „FLUSH“ to

„SPRAY“, and when opening the

spray gun*, the pressure of one

component rises and the other

one falls.

➤

One (automatic-) valve does not

open.

➤

Check valves and repair.

18. When switching from „SPRAY“ to

„FLUSH“, the flush pump does not

operate.

➤

Flush pump is defective.

➤

Flush valve at mixing block does

not open.

➤

Check whether flush pump is in

operation.

➤

Check valves.

➤

Take off flush hose at automatic

valve and replace by a manual

gun.

➤

Test function of flush pump.

19. The air motor of the 2K-unit is

icing rapidly, and the performance

of the unit decreases.

➤

The anti-icing unit is turned off.

➤

The water separator is full.

➤

The equipment is overworked.

➤

Turn on the anti-icing unit and, if

possible, the fluid heater.

➤

Empty the water separator.

➤

Ensure that the equipment does

not run too fast (standard value is

approx. 25 cycles per minute).

20. Air is escaping from the air motor

at the guide axles behind the pro-

tective grates and at the interme-

diate body.

➤

Gaskets of air motor are worn.

➤

Replace gaskets.

21. The air motor stops working, al-

though there is sufficient pressure

at the air supply .

Base and hardener show no pres-

sure.

➤

The control system of the air mo-

tor is defective.

➤

Have the air motor repaired in a

service center.