Commissioning

5

Translation of the original operation manual

29

29

•303_208176_1004_en•ski

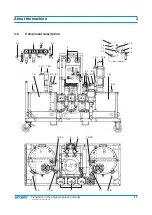

Settings on the mixer (Circulate)

➤

Turn the lever on the external mixer:

➤

SPRAY (pos. 13.2) to “CLOSED”.

➤

FLUSH (pos. 13.3 A / B) to “CLOSED”.

➤

CIRCULATE (pos. 13.1) to “OPEN”.

➤

Set the air regulator (pos. 10.1) on the feed pumps to approx. 3 - 5 bar.

➤

Open the air cut-off ball valve (pos. 2.1) on the maintenance unit.

➤

Release the STOP button (pos. 1.2) and press the START button (pos. 1.1).

➤

Set the air regulator (pos. 2.2) at the main pump to approx. 0,5 - 1 bar.

Open the regulator on the de-icing module.

The air from the compressor is normally sufficient in the summer time. In the cold sea-

sons, the air should be preheated with a flow heater.

If a fluid heater for material heating is installed, this can also be used to warm up the

air for the de-icing module. Please refer to the separate user’s handbook of the fluid

heater!

➤

Allow the rest of the thinner which is in the system to flow via the return hoses (pos. 9)

into an empty open container until the materials which are to be processed appears.

Place the return hoses in the designated material container. Secure the return hoses

in the material container.

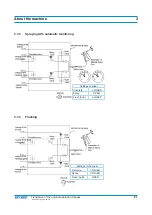

The material heaters in the circuit

➤

Fluid heaters (pos. 11):

➤

Restore the power connection.

➤

Set the designated temperature on the adjusting knob.

➤

Circulate the material slowly through the return hoses until the entire system is bled

of trapped air.

The material in the system will heated by the fluid heaters.

Check the mixing ratio on the dispensing unit (Pos. 5)

➤

Turn the lever on the external mixer:

➤

SPRAY (pos. 13.2) to “CLOSED”.

➤

FLUSH (pos. 13.3 A / B) to “CLOSED”.

➤

CIRCULATE (pos. 13.1) to “CLOSED”.

➤

Place an empty container under each outlet of the dispensing unit.

➤

Open the lever of the dispensing unit (pos. 5).