WORKSHOP MANUAL

Winget Mechanically Fed Mixers

Models: 200TM

From 1998

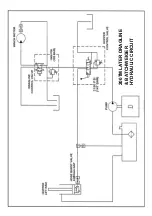

Hydraulic System Description Dragline

The dragline hydraulic system consists of a 12 volt solenoid controlled oil distribution

block (otherwise known as the Dragline Control Block) containing a relief valve set to

a maximum of 1500psi. A hydraulic motor is fitted operating the dragline winch.

The system is continuously supplied with oil whilst the engine or electric motor are

running via a High Pressure Carryover (H.P.C.O) contained within the main control

valve.

When the 12-volt solenoid is not energised oil flow is directed by the control block

back to the hydraulic tank through the return line which terminates at the tee piece on

the side of the tank.

The supply and return hoses supplying oil to the winch motor from the distribution

block are ported within the block to form a closed loop enabling the winch motor to

revolve freely within minimum resistance when the dragline shovel is manually pulled

backwards by the operator.

When the 12-volt solenoid is energised by operating the shovel button/switch, the

tank return is closed, the loop is opened and oil is directed to the winch motor, which

revolves reeling in the dragline shovel. Oil exiting the winch motor is directed by the

control block through the tank mounted tee piece and back into the tank.

Should the motor jam or seize in operation the relief valve in the control block will

“blow off” dumping the oil back to the tank through the tee piece.

Содержание 200TM

Страница 3: ...WORKSHOP MANUAL 200TM SECTION 1 INTRODUCTION...

Страница 6: ...WORKSHOP MANUAL 200TM SECTION 2 REPAIR SERVICE PROCEDURES...

Страница 12: ...200TM DRUM ADJUSTMENT...

Страница 42: ...WORKSHOP MANUAL 200TM SECTION 3 GENERAL ARRANGEMENT DIMENSIONS...

Страница 43: ...GENERAL ARRANGEMENT...

Страница 44: ...DIMENSIONS...

Страница 45: ...WORKSHOP MANUAL 200TM SECTION 4 SERVICE SCHEDULES LUBRICATION DIAGRAM...

Страница 48: ...LUBRICATION POINTS...

Страница 49: ...LUBRICANTS...

Страница 50: ...WORKSHOP MANUAL 200TM SECTION 5 HYDRAULIC CIRCUIT DIAGRAMS...

Страница 51: ...200TM LATER BASIC HYDRAULIC CIRCUIT...

Страница 52: ...200TM LATER DRAGLINE BATCHWEIGER HYDRAULIC CIRCUIT...

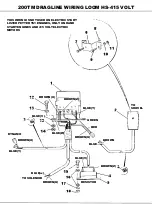

Страница 53: ...WORKSHOP MANUAL 200TM SECTION 6 WIRING DIAGRAMS...

Страница 59: ...Hourmeter lamp dwg 04 03 02 12 50 36 Scaled to fit...

Страница 60: ...Hourmeter no lamp dwg 04 03 02 12 53 33 Scaled to fit...

Страница 62: ...WORKSHOP MANUAL 200TM SECTION 7 NOISE LEVELS...

Страница 64: ...WORKSHOP MANUAL 200TM SECTION 8 SPECIAL TOOLS...

Страница 65: ...200TM PUNCH VALVE SEAT 200TM SPECIAL TOOL V2003698 CASE HARDEN TO 45 50 ROCKWELL...

Страница 66: ...200TM DRUM BLADE DRILLING GUIDE SPECIAL TOOL 200TM 513360100...

Страница 67: ...200TM SPECIAL TOOLS...

Страница 68: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Страница 69: ...WORKSHOP MANUAL 200TM SECTION 9 HYDRAULIC CONTROL VALVE SERVICE MANUAL...

Страница 70: ...PAGE INTENTIONALLY BLANK...

Страница 71: ...WORKSHOP MANUAL 200TM SECTION 10 PARTS LISTINGS...

Страница 73: ...200TM MAINFRAME AXLES AND STABILISERS...

Страница 90: ...200TM 415 VOLT START STOP SWITCH STAR DELTA...

Страница 92: ...200TM 415 VOLT START STOP SWITCH DIRECT ON LINE...

Страница 94: ...200TM HOPPER CRADLE BASIC NON WEIGHER COAT ALL PINS AND BEARINGS WITH COPPERSLIP BEFORE INSTALLATION...

Страница 98: ...200TM HOPPER...

Страница 99: ...1 513310900 HOPPER ASSEMBLY 1 2 172S05D BOLT COACH 8 3 267S07 WASHER FLAT 8 4 61S05 NUT BINX 8 200TM HOPPER...

Страница 110: ...200TM WATER TANK FIT SPECIAL WASHER V2004220 BETWEEN ITEMS 11 12...

Страница 114: ...200TM DYNAMO AND MOUNTING LISTER PETTER TS1 HS...

Страница 118: ...200TM DRAGLINE ASSEMBLY...

Страница 120: ...200TM DRAGLINE ASSEMBLY...

Страница 124: ...200TM DRAGLINE SHOVEL...

Страница 126: ...200TM DRAGLINE FEEDAPRON...

Страница 128: ...200TM BATTERY TRAY LISTER PETTER TS1 ES WELD TRAY TO THE REAR OF THE MAINFRAME BELOW THE ENGINE HOUSING...

Страница 130: ...200TM LISTER PETTER TS1 ELECTRIC START...

Страница 132: ...200TM DECALS AND LOGOS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22...

Страница 134: ...200TM DECALS AND LOGOS 23 24 25 26 27 28 29...

Страница 135: ...200TM SPECIAL TOOLS...

Страница 136: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Страница 137: ...WORKSHOP MANUAL 200TM SECTION 11 BATCHWEIGHER MAINTENANCE INSTRUCTIONS...

Страница 138: ...MAINTENANCE INSTRUCTIONS HYDRAULIC WEIGHING UNITS WWW WINGET CO UK...

Страница 140: ......

Страница 141: ......

Страница 142: ......

Страница 143: ......

Страница 144: ......

Страница 145: ......

Страница 146: ......

Страница 147: ......

Страница 148: ...WORKSHOP MANUAL 200TM SECTION 12 18 BLANK...