30

31

English

English

In the case of larger deviations, please consult the manufacturer.

Please consult the appropriate operating manual for details on

inspecting the safety and monitoring devices on the auxiliary

lifting gear.

Changing the lubricant

The drained lubricant must be checked for dirt and water

content. If the lubricant is very dirty and contains more than

1/3 water, it must be changed again after four weeks. If there

is again water in the lubricant then, it seems likely that a seal

is defective. In this case, please consult the manufacturer. If a

sealing room or leakage monitoring system is being used, the

display will light up again within four weeks of changing the

lubricant if a seal is defective.

7.5 Repairs

When carrying out repair work, the following information

should always be noted:

- Round sealing rings as well as existing seals should always

be replaced.

- Screw fixings such as spring washers or the self-locking

Nord-Lock screw fixing should always be replaced.

- If no self-locking Nord-Lock screw fixing is used as a locking

screw or it is not possible to use these, then no dacromet-

coated screw should be used. In this case, screws made from

the material A2 or A4 must be used. The correct torques

must be observed.

- Never use brute force during this work.

Changing sealing parts

Changing sealing parts on the liquid side such as the block seal

cartridge and the mechanical seal shaft requires a certain amount

of specialist knowledge about these sensitive components.

In addition to this, in order to carry out the work, much of the

machine must be dismantled.

8 Shutdown

8.1 Temporary shutdown

For this type of shutdown, the machine remains installed

and is not cut off from the electricity supply. For temporary

shutdown, the machine must remain completely submerged so

that it is protected from frost and ice. Make sure the operating

room and the pumped fluid cannot be covered by ice. This

ensures that the machine is always ready for operation. During

longer shutdown periods, carry out a regular (monthly to

quarterly) function run for a period of 5 minutes.

8.2 Final shutdown / storage

Beware of hot parts!

When removing the machine, be careful of the

temperature of the housing components. These can

heat up to well above 40° C. Let the machine cool down

to ambient temperature before you touch it.

Switch off the system, disconnect the machine from the electricity

supply and dismantle and store it. Note the following information

concerning storage:

- Clean the machine.

- Store it in a clean, dry place, protect the machine against

frost.

- Place it down vertically onto a firm foundation and secure it

against falling.

- Seal the intake and discharge ports of pumps with suitable

material (such as foil).

- Support the electric connecting lead on the cable lead-in to

help avoid a permanent deformation.

- Protect the ends of the electric power cable from moisture.

- Protect the machine from direct sunshine as a preventive

measure against brittleness in elastomer parts and the

propeller and casing coating.

- When storing the machine in a garage please remember:

Radiation and gases which occur during electric welding

destroy the elastomers of the seals.

- During lengthy periods of storage, regularly (for example

every six months) turn the impeller or propeller by hand.

This prevents indentations in the bearings and stops the

rotor from rusting up.

8.3 Restarting after an extended period of storage

Before restarting the machine, clean it of dust and oil deposits.

Then carry out the necessary mainte-nance actions (see

“Maintenance”). Check that the mechanical shaft seal is in

good order and working properly.

Once this work has been completed, the machine can be

installed (see “Installation”) and connected to the electricity

supply by a specialist. See “Startup” a for instructions on

restarting.

Only restart the machine if it is in perfect condition and ready

for operation

9 Troubleshooting

In order to prevent damage or serious injury while rectifying

machine faults, the following points must be observed:

- Only attempt to rectify a fault if you have qualified staff. This

means each job must be carried out by trained specialist

staff, for example electrical work must be performed by a

trained electrician.

- Always secure the machine against an accidental restart by

disconnecting it from the electric system. Take appropriate

safety precautions.

- Always have a second person make sure the machine is

switched off in an emergency.

- Secure moving parts to prevent injury.

- Independent work on the machine is at one's own risk and

releases the manufacturer from any warranty obligation.

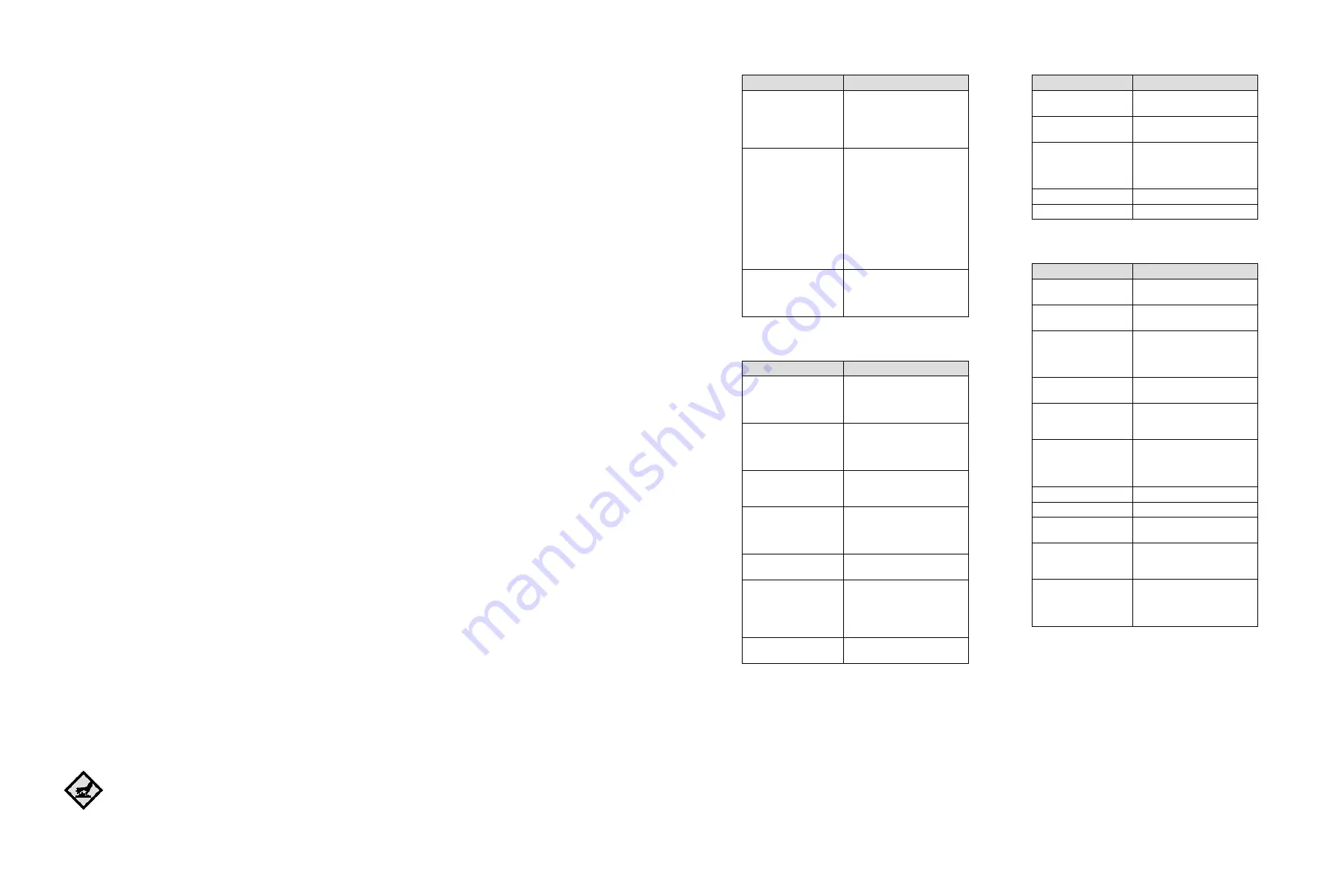

Fault1: The machine will not start

Cause

Remedy

Electricity supply

interrupted – short circuit

or

earth connection in the

cable or motor windings

Have the motor and wires

checked by a specialist and

replaced if necessary

Fuses, the motor

protection switch and/

or monitoring devices are

triggered

Have a specialist inspect the

connection and correct them as

necessary

Have the motor protection

switch adjusted

according to the technical

specifications, and reset

monitoring equipment

Check that the impeller/

propeller runs smoothly. Clean it

or free it as necessary

The moisture sensors

(option) has interrupted

the power circuit

(operator-related)

See fault: Mechanical shaft seal

leaks, sealing chamber monitor

reports fault and switches

the machine off

Fault2: The motor starts, but the motor protection switch

triggers shortly after start-up

Cause

Remedy

The thermal trigger on

the motor protection

switch is incorrectly set

Have a specialist compare the

setting of the trigger with the

technical specifications and

adjust it if necessary

Increased power

consumption due to

major voltage drop

Have an electrician check the

voltage on each

phase and rewire if necessary

Two-phase operation

Have a specialist inspect the

connection and correct it as

necessary

Excessive voltage

differences on the three

phases

Have a specialist inspect the

connection and the switching

system and correct it as

necessary

Incorrect direction of

rotation

Swap the 2 phases from the

mains supply

Impeller/propeller

impeded by adhesive

material, blockages and/

or solid matter, increased

current consumption

Switch off the machine, secure

it against being switched on

again and free the impeller/

propeller or clean the suction

port

The pumped fluid is too

dense

Contact the manufacturer

Fault3: Machine runs but does not pump

Cause

Remedy

No pumped fluid

Open the container intake or

sliders

Intake blocked

Clean the intake, slider, suction

port or intake strainer

Impeller/propeller blocked

or obstructed

Switch off the machine, secure

it against being switched on

again and free the impeller/

propeller

Defective hose or piping Replace defective parts

Intermittent operation

Check the control panel

Fault4: The machine runs, but not at the stated operating

levels

Cause

Remedy

Intake blocked

Clean the intake, slider, suction

port or intake strainer

Slide in the discharge line

closed

Fully open the slide

Impeller/propeller blocked

or obstructed

Switch off the machine, secure

it against being switched on

again and free the impeller/

propeller

Incorrect direction of

rotation

Replace 2 phases on the mains

supply

Air in the system

Check the pipes, pressure

shroud and/or pump unit, and

bleed if necessary

Machine pumping against

excessive pressure

Check the slide in the discharge

line, if necessary open it

completely, use a different

impeller or contact the factory

Signs of wear

Replace worn parts

Defective hose or piping Replace defective parts

Inadmissible levels of gas

in the pumped liquid

Contact the factory

Two-phase operation

Have a specialist inspect the

connection and correct it as

necessary

Excessive decrease in the

water table during operation

Check the supply and capacity

of the system, and inspect

the level control settings and

function