2. Electroforming

9

Parts which are intended for veneering must be

electroformed with a minimum plating thickness of

0.2 mm.

To electroform bars please see

chapter 3 page 13

.

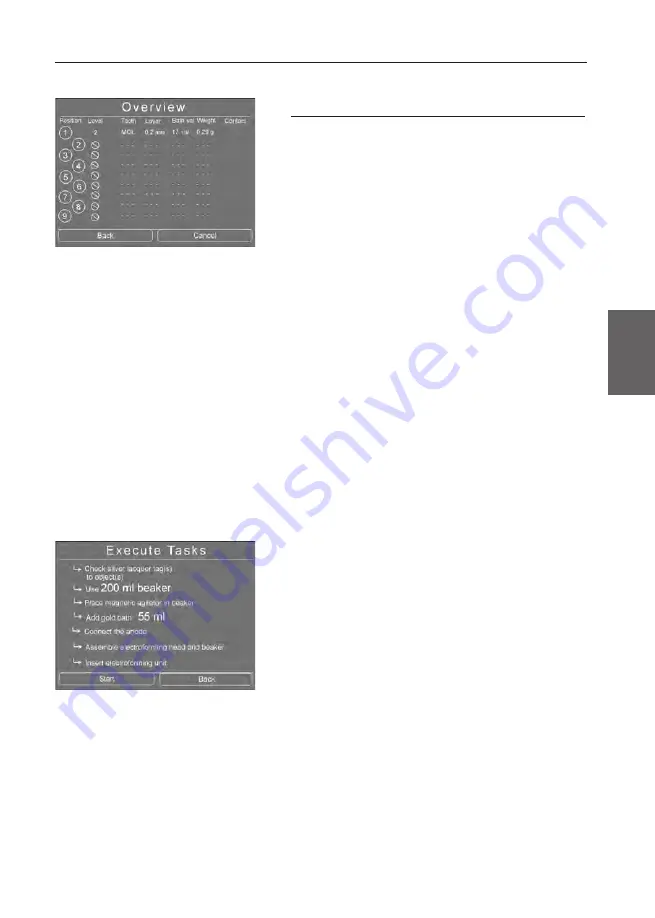

Press the

"Continue" button to return to the input

menu and, if necessary, select the next position and

enter its parameters.

Repeat these steps until the

parameters for all the parts have been entered. The unit

automatically adds the amount of goldplating bath

required and displays the weight of gold for each level.

If you leave out individual positions, the unit automati-

cally assumes that the position has not been used and is

therefore not assigned. Press the

"Overview"

button to

go to the "Overview" menu.

The selected positions are listed here. You can change a

position by selecting it.

Press the

"Back"

button to return to the input menu.

Press the

"Continue"

button in the input menu to go to

the following menu:

"Execute tasks"

.

2.4.3. Assembling the electroforming cell

Measure the amount of goldplating bath required and

pour it into the selected electrolyte reservoir with the

corresponding magnetic agitator rod.

Place the electroforming head with the anode and

assembled parts into the glass beaker and lock the cell

with the sealing clip.

Place the electroforming cell in the unit.

e

n

g

li

sh

Important:

!