8

Master Programming Mode

When the Master Programming Mode is entered, all

available option setting displays may be viewed and set

as needed. Depending on current option settings, some

parameters cannot be viewed or set.

Setting the Time of Day

1. Press and hold either the Up or Down buttons until the

programming icon replaces the service icon and the

parameter display reads TD.

2. Adjust the displayed time with the Up and Down buttons.

3. When the desired time is set, press the Extra Cycle button

to resume normal operation. The unit will also return

to normal operation after 5 seconds if no buttons are

pressed.

Entering Master Programming Mode

Set the Time Of Day display

to 12:01 P.M. Press the Extra

Cycle button (to exit Setting

Time of Day mode). Then

press and hold the Up and

Down buttons together until the programming icon replaces

the service icon and the Display Format screen appears.

Exiting Master Programming Mode

Press the Extra Cycle button to accept the displayed settings

and cycle to the next parameter. Press the Extra Cycle

button at the last parameter to save all settings and return

to normal operation. The control will automatically disregard

any programming changes and return to normal operation

if it is left in Master Programming mode for 5 minutes without

any keypad input.

Resets

:

Soft Reset:

Press and hold the Extra Cycle and Down buttons

for 25 seconds while in normal Service mode. This resets all

parameters to the system default values, except the volume

remaining in meter immediate or meter delayed systems

and days since regeneration in the time clock system.

Master Reset:

Hold the Extra Cycle button while powering up

the unit. This resets all of the parameters in the unit. Check

and verify the choices selected in Master Programming

Mode.

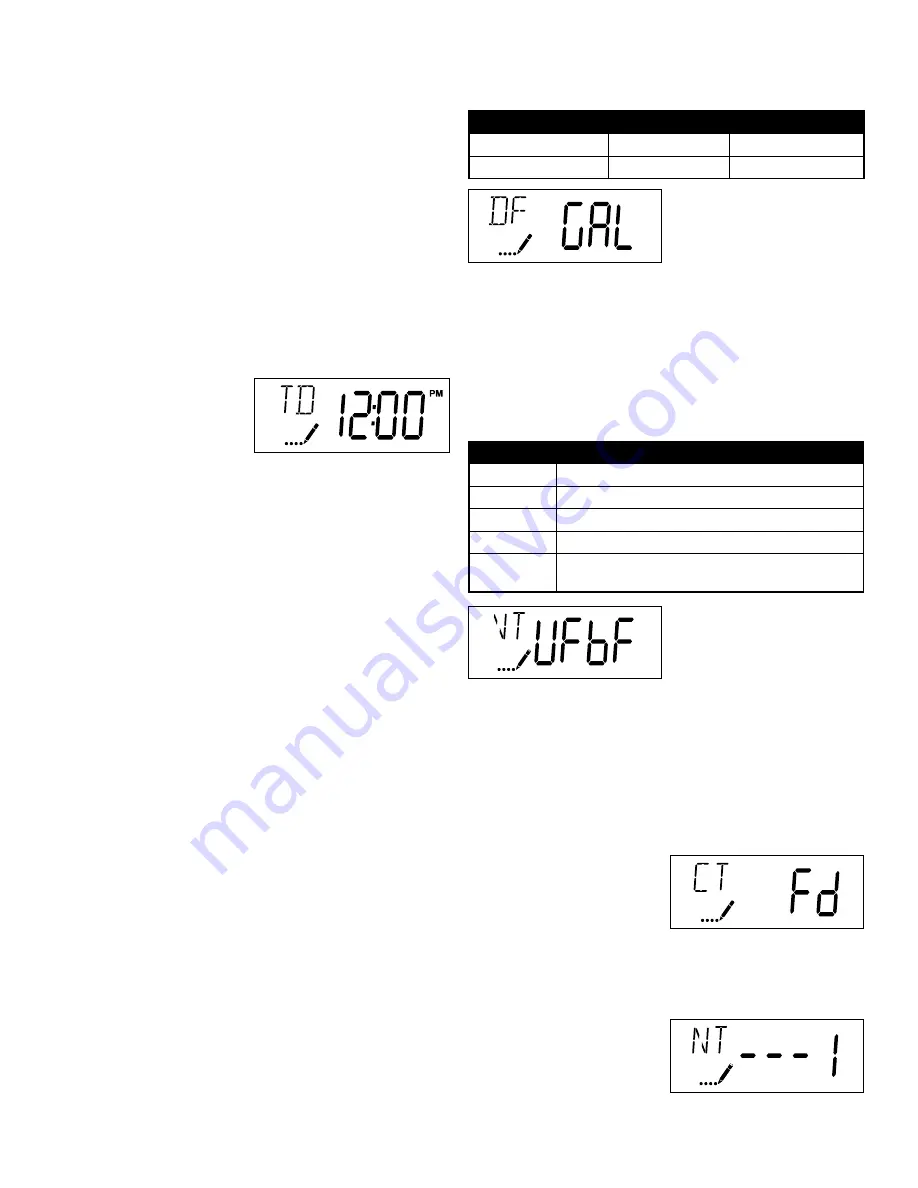

1. Display Format (Display Code DF)

This is the first screen that appears when entering Master

Programming Mode. The Display Format setting specifies

the unit of measure that will be used for volume and how

the control will display the Time of Day. This option setting

is identified by “DF” in the upper left hand corner of the

screen. There are three possible settings:

CAUTION: Before entering Master Programming, please contact your local professional water dealer.

Display Format Setting

Unit of Volume

Time Display

GAL

U.S. Gallons

12-Hour AM/PM

Ltr

Liters

24-Hour

225

2. Valve Type (Display Code VT)

Press the Extra Cycle button. Use this display to set the Valve

Type. The Valve Type setting specifies the type of cycle

that the valve follows during regeneration. Note that some

valve types require that the valve be built with specific

subcomponents. Ensure the valve is configured properly

before changing the Valve Type setting. This option setting

is identified by “VT” in the upper left hand corner of the

screen. There are 2 possible settings:

3. Control Type (Display Code CT)

Press the Extra Cycle button. Use this display to set the

Control Type. This specifies how the control determines when

to trigger a regeneration. For details on how the various

options function, refer to the “Timer Operation” section of

this service manual. This option setting is identified by “CT” in

the upper left hand corner of the screen.

There are four possible settings:

Meter Delayed: Fd

Meter Immediate: FI

Time Clock: tc

Day of Week: dAY

4. Number of Tanks (Display Code NT)

Press the Extra Cycle button. Use this display to set the

Number of Tanks in your system. This option setting is

identified by “NT” in the

upper left hand corner of the

screen. There are two possible

settings:

Single Tank System: 1

Abbreviation

Parameter

df1b

Standard Downflow/Upflow Single Backwash

df2b

Standard Downflow/Upflow Double Backwash

Fltr

Filters

UFbF

Upflow Brine First (used for 6200 upflow softener valve)

UFtr

Upflow Filter to be used with 6200 upflow backwashing

filter valve

Содержание 6200 SXT

Страница 1: ...6200 SXT Upflow Control Valve for Water Conditioning and Treatment Purposes Service Manual...

Страница 21: ...Wiring Diagram 21...

Страница 22: ...6200SXT Upflow Brining Rates 22 6200SXT Upflow Brining Rates with Water 20 PSI Regulated Cap...

Страница 29: ...29 6200 SXT Valve Dimensional Drawings All dimensions are in Inches mm...

Страница 35: ...35...