Leak-tightness of the drainage connection of the condensation

line shall be ensured. However, pour approximately 1-liter

water into the internal flue prior to fitting the flue bend of the

flusher in the boiler against the gas leak risk during start-up. Thus,

exhaust gas leakage will be prevented thanks to the water in the

flusher.

Slope of the condensate water hose and line shall always be

downwards

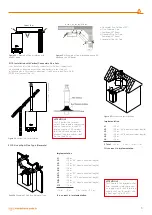

2.1.9. Exhaust Gas Flue Pipe Set and Accessories Connection

Flue accessory sets to be used in exhaust gas installation of

hermetic boilers shall be original Warmhaus flue sets and they

shall be used by observing measurements and restrictions

given in installation instructions.

In case of using exhaust gas pipe and/or accessories other

than Warmhaus original exhaust gas flue pipes and

accessories, boiler shall not be commissioned by the

Authorized Service and thus, no warranty is provided!

The boiler shall only be installed with original Warmhaus air suction and

exhaust gas discharge device made of plastic material.

Plastic channels cannot be installed without suitable protection against

UV and weather conditions to distances over 40 cm and outsides.

Every pipe is defined with an explanatory and discriminative

Warmhaus mark mentioned in remarks.

IMPORTANT

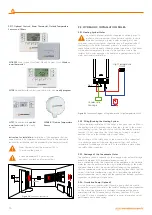

When carrying out commissioning of the boiler, you are highly

recommended to perform the following checks:

- Make sure that there are no liquids or inflammable materials in the

immediate vicinity of the boiler.

- Make sure that the electrical connections have been made correctly

and that the earth wire is connected to a good earthing system.

- Open the gas valve and check the soundness of the connections,

including that of the burner to fan and burner hood to heat

exchanger

- Make sure that the boiler is set for operation for the type of gas

supplied.

- Check that the flue pipe for the outlet of the products of the

combustion is unobstructed and has been properly installed.

- Make sure that any shutoff valves are open.

- Make sure that the system is charged with water and is thoroughly

vented.

- Check that the circulating pump is not jammed.

- Purge the system, bleeding off the air present in the gas pipe by

operating the pressure relief valve on the gas valve inlet.

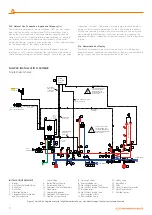

2.1.7. Heating and Domestic Hot Water Installations

Radiator and ground heating installation shall be configured in

accordance with technical specifications of the TSE (Turkish Standards

Institution) and MMO (Chamber of Mechanical Engineers), and

according to the heat loss calculation. Radiator type and amount and

ground heating installation pipe amount shall comply with the heat loss

calculation.

• The design pressure strength of the heating installation shall be

minimum 6 bar.

• If the mains pressure is more than 6.5 bar, a pressure reducer must

be fitted.

• It is recommended to construct the radiator installation as double

line and without using bends and joints as much as possible.

• Strainer filter shall be installed in heating return and tap water (city

network) intake line if a boiler is to be used.

• An additional expansion tank with 50 liters capacity shall be used

depending upon the volumetric capacity of the heating water of the

heating circuit (closed circuit) and working temperature.

• If room thermostat and thermostatic radiator valve are to be used

together; thermostatic valve shall not be installed in radiators in the

place where room thermostat is present.

• Cross connection must be made for efficient functioning in radiators

longer than 1,5 m.

• Covers shall be used for radiator and domestic hot water wall

passages and fixed with wall clamps to prevent expansions due to

heating.

• An external boiler shall be fitted to the boiler for supply of domestic

hot water. In case of using domestic water boiler, the three-way

valve and boiler sensor within the product accessories.

• The heating installation must be washed and cleared off dirt before

filling!

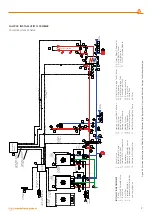

2.1.8. Filling the flusher for Condensation Line

After the wall mounting operation of condensing boiler, electrical

connections, radiator lines, hot tap water connections and

condensation water drainage line are completed, condensation flusher

shall be filled with water (Figure 8).

Figure 8

Filling the condensation flusher

Figure 9

There is a Warmhaus logo on the flue bend.

9

Содержание VIWA 50

Страница 1: ...WALL MOUNTED CONDENSING BOILERS INSTALLATION USER MANUAL VIWA50 VIWA65...

Страница 2: ...Viwa 50 Viwa 65...

Страница 35: ...50 61 Viwa 50 65 58 Viwa 65 35 35...