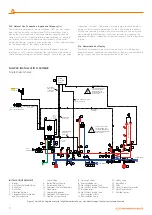

Fi

gur

e

38

C

as

ca

de

Sy

st

em

wi

th

Vi

w

a

50-6

5 Boi

ler

s

and

1

R

ad

ia

tor

(Hi

gh

Temper

atur

e)

Ci

rcui

t

and

Hot

W

at

er

S

tor

ag

e

Ta

nk

Scheme E

xa

mpl

e

C

OLD

WAT

E

R

RECIRCULATION CIRCUIT

C

OLD

WAT

E

R

G

AS

PIPELINE

FL

UE

FL

UE

S

ys

tem P

ump

Hy

dr

aulic

Seper

at

or

Sensor 2 x 1.

0 mm

2

R

ecir

cula

tion P

ump

S

tor

age T

ank P

ump

S

tor

age T

ank Sensor

2 x 1.

0 mm

2

OpenT

herm

C

onnection

2 x 1.

0 mm

2

OpenT

herm

C

onnection

2 x 1.

0 mm

2

P

ump Cable

3 x 1.

0 mm

2

P

ump

Cable

3 x 1.

0 mm

2

OpenT

herm

C

onnection

2 x 1.

0 mm

2

1. Z

one + S

tor

age T

ank

Timer / R

oom T

hermos

tad

Timer / R

oom T

hermos

tad

2 x 1.

0 mm

2

Outside Sensor 2 x 1.

0 mm

2

S

ys

tem P

ump - Boiler

P

anel - R

ela

y C

onnection

3 x 1.

0 mm

2

Electrical P

anel

S

tor

age T

ank - Boiler P

ump

P

anel - R

ela

y C

onnection

3 x 1.

0 mm

2

2. Boiler

/Sla

ve

1. Boiler

/Mas

ter

6. Boiler

/Sla

ve

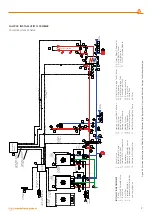

INS

TALL

ATION E

QUIPMENT

1.

Boiler

2.

G

as S

af

et

y Solenoid V

alv

e

3.

B

all V

alv

e

4.

G

as Filt

er

5.

V

ibr

ation Isola

tor

6.

C

ondensa

te W

at

er Siphon

and Dr

ainage Line

7.

Check

-V

alv

e

8.

Boiler (R

eturn) Pump

9.

A

ut

oma

tic Air V

en

t

1 O

. Sedimen

t-Dirt

-Air Separ

at

or

11

.

Manome

ter

12.

Hy

dr

aulic Separ

at

or Sensor

13.

Hy

dr

aulic Separ

at

or

14.

Sedimen

t-Dirt

-Separ

at

or

15.

Hea

ting S

ys

tem Flo

w C

ollec

tor

16.

Hea

ting S

ys

tem

R

eturn C

ollec

tor

17

.

Hea

ting S

ys

tem Pump

18.

Hea

ting S

ys

tem

19

.

Pr

es

sur

e R

educ

er

20

.

Hot W

at

er S

tor

age T

ank

21

.

Hot W

at

er S

tor

age T

ank Pump

22.

Hot W

at

er S

tor

age T

ank Sensor

23.

Air Separ

at

or

24.

Hot W

at

er S

tor

age T

ank

R

ecir

cula

tion Cir

cuit

25.

R

ecir

cula

tion Pump

26.

S

af

et

y v

alv

e

27

. V

es

sel T

ank

28. Filt

er

29

.

Timer / R

oom T

hermos

ta

t

30

.

Main Elec

tric P

anel

31

.

Outside Sensor

37

.

ML

C 2

7 C

ascade Module

SAMPLE INSTALLATION SCHEME

Cascade System Scheme

19

Содержание VIWA 50

Страница 1: ...WALL MOUNTED CONDENSING BOILERS INSTALLATION USER MANUAL VIWA50 VIWA65...

Страница 2: ...Viwa 50 Viwa 65...

Страница 35: ...50 61 Viwa 50 65 58 Viwa 65 35 35...