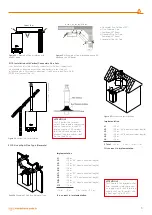

2.1.14. Installation at Partially Protected Outsides

Installation Instructions:

This combi can be installed in partially

protected outsides Partially protected area means the place where the

boiler will not be directly exposed to atmospheric factors and weather

conditions (rain, snow, etc.)

Frost Protection:

The boiler is equipped with a system that prevents

frost by automatically activating the pump and boiler when the internal

water is lower than 5°C.

Frost protection function only depends on below given conditions:

-If the combi is correctly connected to gas and electrical sources;

-If the combi is supplied from gas and electricity sources in a fixed way;

-If the Combi is not in failure situation due to lack of ignition;

-If radiator installation pressure is full and radiator valves are open;

The boiler is protected against frost up to -5°C ambient temperature.

Lowest Temperature -5°C.

In case the boiler is installed in an

environment with a temperature lower than -5°C, and gas supply is

interrupted or passed into failure due to failing to make ignition, Frost

Prevention System shall not be activated and frost/failure shall occur in

the device. Following instructions should be followed for preventing the

risk of frost:

- Heating circuit, into antifreeze (special heating devices) a good brand of

antifreeze manufacturer's instructions are followed carefully so as it deems

necessary for the rate and the minimum temperature is desired to be stored

in the heater frost protection with the matter.

Materials used for manufacturing the combi are resistant against glycol and

propylene based anti-frost liquids. Follow warnings of supplier company

regarding their technical service life and possible disposals.

Frost / icing protection of the combi is guaranteed only under these

conditions:

Any damages caused by noncompliance to the terms specified above

and power loss are excluded from warranty.

If the boiler is installed in places where temperature drops below

0°C (both for hot domestic water and heating purposes), pipes of the

heating system and domestic water installation must be insulated.

2.1.15. Electrical Connections

Ensure electrical safety of boiler by connecting to an effective earthing

installation that follows safety instructions in force.

Earthing shall not be performed through the neutral line on the socket

in places without earthing! It is dangerous and unacceptable to use gas

and water connection pipes for earthing.

WARMHAUS A.Ş. cannot be held responsible for any damage or

loss to individuals or property arising from failing to provide earth

connection of the boiler and not being fitted by a competent

Electrician or registered individual in accordance with directives and

standards in force in the country where the boiler is installed.

Also, ensure that the electricity installation complies with the maximum

power to be supplied as indicated in technical specifications label.

boiler shall be energized with "X" type socketless special power supply

cables. "Warmhaus boiler has an IPX5D protection level. Power supply cable

should be connected to 230 V +%10; -%15 50Hz grid with L-N poles and

relying on the earth connection, high voltage category 3rd class multiple

poled disconnected should be envisaged on the same grid. Contact our

Authorized Warmhaus Service for replacement of the cable.

The power supply cable must follow the specified route. In

case of replacing fuses on the board, use 2A or 3,15A quick

type fuse.

In order to feed the device from the mains, adapter, multiple sockets

and extension cables are not permitted.

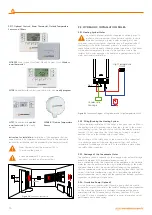

2.1.16. Optional Controls: Room Thermostat, Outside Temperature

Sensor and Others

Room thermostat, External Weather Temperature Sensor, etc. control

devices must be connected to Warmhaus boiler devices by the

authorized service personnel; In case connections are performed by

unauthorized persons, boiler warranty shall be void.

Room thermostat, outside Temperature Sensor, etc. control

devices are provided as optional accessories for Warmhaus

boiler devices and they must be Warmhaus approved.

Please follow instructions of use for placement of outside Temperature

Sensor.

This sensor can be directly connected to electrical installation of

the boiler, and it automatically reduces the maximum return water

temperature in the installation when outside temperature rises for

enabling functioning according to outside temperature changes sent

to radiator installation outside Temperature Sensor is activated when

connected as independent from the used room thermostat typology

and functions together with room thermostats. The relation between

installation input temperature and outside temperature is defined

according to curves in the diagram from position of the button located

on the panel of boiler (or on the control panel if connected to boiler

(Figure 39).

Electrical connection of the Outsides Weather Temperature Sensor

shall be made to the terminals to which the White & White cables

of the Aux cable connected to the electronic card of the boiler are

connected (Figure 27).

24V AC

G S M

OT

THERMOSTAT BRIDGE

OPENTHERM CONTACT

OUTDOOR TEMPERATURE SENSOR

WHITE

ORANGE

TO PCB

THERMINAL

OPEN THERM

CONNECTION

ORANGE

WHITE

A

PCB

PCB

PCB

BLUE

BROWN

DHW TANK PROBE

PCB

PCB (A8)

BLACK

3-WAY VALVE

CH OPEN

PHASE (L1)

DHW OPEN

PHASE (L2)

NEUTRAL (N)

OUTDOOR

TEMPERATURE

SENSOR

WHITE

ORANGE

GREEN

GREEN

BLUE

BROWN

B

Attention: During

ON-OFF and

Room Thermostat

connections, B

Bridge cable shall

be disconnected.

Şekil 27

Kazan oda termostatı ve dış hava sıcaklık sensörü bağlantıları.

15

Содержание VIWA 50

Страница 1: ...WALL MOUNTED CONDENSING BOILERS INSTALLATION USER MANUAL VIWA50 VIWA65...

Страница 2: ...Viwa 50 Viwa 65...

Страница 35: ...50 61 Viwa 50 65 58 Viwa 65 35 35...