4) Do not turn on the power to the freezer or the condensing unit until the refrigeration lines have been

connected and the system has been charged with refrigerant. Label the circuit breakers with information

regarding which cylinder and condensing unit the breaker is designated for to prevent confusion if

power ever needs to be shut off.

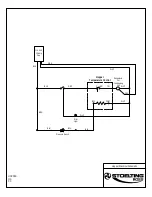

5) When connecting power to the freezer, run the line under the freezer and through the bottom of the

electrical box. Remove the electrical box cover by loosening the four screws. The screws do not have to

be removed. Connect the power to the 4-circuit terminal strip. The 4-circuit terminal strip is labeled L1,

L2, L3, and GND. After connections are made, place the cover on the electrical box, but do not tighten

the cover (for single-phase freezers the cover can be tightened). The electrical box may need to be

accessed when checking for proper rotation of the motor.

Step 3 Plumbing Connections:

1) On water-cooled freezers, the water inlet is a standard garden hose connection and the water outlet is

5/8” OD copper tubing. The connections are located at the back of the freezer. Remove the rear panel to

access the connections. Run the plumbing under the freezer frame. Water-cooled freezers use

approximately 3 gallons of 75°F water per minute while in use (the M202 uses 2 gallons per minute).

The freezer does not use any water when not in use.

2) The freezer is equipped with a dipping trough that requires a water inlet line and a drain line. The

water inlet has a 5/16” OD brass female connector (the M202 female connector is 1/4” OD). Solder a

5/16” line to the water valve inlet using silver solder (the M202 requires a 1/4” line). Install a shutoff

valve in the water inlet line. The drain connection is 1-1/2”. Run a drain line from the trough to a drain

on the floor. Leave enough slack in the drain line so that the lower front panel can be easily removed for

service.

3) If the freezer is equipped with the hopper faucet option, run the hopper faucet tubing to the dipping

trough inlet and install a T. This will supply water needed for the hopper faucet and the water valve for

the dipping trough.

Step 4 Receiving and Installing Remote Condensing Units:

* The remote condensing units may be sent prior to delivery of the freezer.

* The freezer requires one remote condensing unit per cylinder.

1) Upon arrival, check the entire remote condenser units for any damage that may have occurred during

transit. With the method of packaging used, the remote condensers should arrive in excellent condition.

The carrier is responsible for all damage in transit, whether visible or concealed

. Do not pay the

freight bill until the remote condenser units have been checked for damage. Have the carrier note any

visible damage on the freight bill. If concealed damage or a shortage is found later, advise the carrier

within 10 days and request inspection. The customer must place a claim for damages and/or shortages in

shipment with the carrier. Stoelting cannot make any claims against the carrier.

2) Remove cardboard covering off the condensing units.

3) Place the condensing units in their predetermined location, either on the roof or on the ground. A

crane or forklift will be needed if the units will be placed on a roof. The condensing units weigh

approximately 200 lbs. each.

Содержание Stoelting CC101A

Страница 1: ...Model CC101A OPERATORS MANUAL Manual No 513616 Rev 6 ...

Страница 2: ......

Страница 14: ......

Страница 16: ...001 1332808 2 ...

Страница 26: ......

Страница 30: ......

Страница 32: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......