Step 7 Running product and setting pressures for the custard freezer:

* Complete the

Custard Freezer Start-Up and Training Checklist

located with the spare parts kit or

in the back of this manual and send it to Stoelting.

1) Remove all spare parts from the hopper before running product. Unwrap the parts and check for

damage. Refer to the list in the manual to make sure no parts are missing. The cylinders need to be under

a load to set the pressures. If custard is not available, run the machine for two minutes and check for

frost in the freezing cylinder. This will indicate that the refrigeration is functioning.

2) Disassemble, clean and sanitize each freezing cylinder. Refer to the manual for proper instructions.

3) After assembling and sanitizing the freezer, add custard mix to the hopper. Follow the instructions in

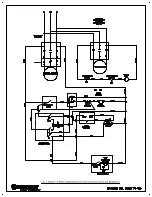

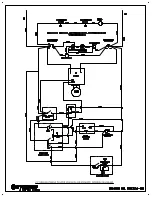

the manual to start freezing the custard (run one cylinder at a time to set the pressures). Connect gauges

to the suction line and the discharge line. When product starts coming out of the faceplate, locate the low

pressure gauge on the front of the freezer and set the AXV to 30 psi. Remove the white plastic cap from

the AXV and turn the valve counterclockwise to decrease the pressure or clockwise to increase the

pressure. Turn the valve 1/4 turn at a time and wait at least 1 minute before making another adjustment.

Connect a gauge to the suction line at the compressor and make sure the pressure is 25 psi. Adjust the

crankcase pressure regulator (CPR) if the pressure is not correct. Remove threaded brass cap on the front

of the CPR and adjust the valve with a 5/16” Allen wrench. Connect a gauge to the suction line at the

hopper and adjust the hopper AXV to 55 psi.

4) Check the faceplate to see if the custard is at the desired texture and temperature. The standard

normal serving temperature of frozen custard coming out of the freezer is 18°-22°F.

5) Set the pressures for the remaining cylinders.

* If the freezer is water-cooled, the discharge pressure was already set at the factory. Run custard mix

through the freezer to double-check and fine-tune the discharge pressure for the particular mix being

used.

* The remote condenser unit has a head pressure control set for a minimum of 255 psi.

* Chocolate and vanilla mixes run differently. Usually the pressures in the chocolate cylinder will need

to be set slightly lower than the pressures in the vanilla cylinder. Custard mixes that use an extract

flavoring will also run differently. Try different pressure settings by adjusting the AXV. Adjust the

pressure setting between 28-32 psi (the freezer will not operate correctly if the AXV is set lower than 28

psi).

6) If the freezer is equipped with the lemon ice option, set the lemon ice AXV. The lemon ice option is

designated for one cylinder (right cylinder). With the system still running product, turn the lemon ice

switch on. The AXV is located behind the cylinder in front of the freezer. Set the lemon ice AXV for 40

psi.

7) When testing is done, take the cylinders apart and clean the custard freezer. Refer to operations

manual under shutdown and disassembly.

Содержание Stoelting CC101A

Страница 1: ...Model CC101A OPERATORS MANUAL Manual No 513616 Rev 6 ...

Страница 2: ......

Страница 14: ......

Страница 16: ...001 1332808 2 ...

Страница 26: ......

Страница 30: ......

Страница 32: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......