Custard Freezer Start-Up and Training Checklist

Distributor Instructions:

Complete this form, obtain customer comments and signature and send to:

502 Hwy 67

Kiel WI 53042

NOTE:

A separate form must be submitted for each individual freezer.

BUYER INFORMATION

FREEZER INFORMATION (See freezer I.D. plate)

Installed at (business name): ____________________________________

Contact person: _______________________________________________

Check one:

Check one:

Check one:

Address: ____________________________________________________

115 volts

single phase

air-cooled

City: ________________________________________________________

208 volts

three phase

water-cooled

State:________ Zip: __________ Phone: ( ) __________________

230 volts

air remote

DISTRIBUTOR INFORMATION

APPOINTMENT SCHEDULES

Business Name: _______________________________________________

Check-out/start-up scheduled for: ___/___/___ at _____AM/PM

Account Number: ______________________________________________

Appointments arranged by: ____________________________

AUTHORIZED SERVICE COMPANY (IF DIFF. THAN DISTR.)

with (buyer contact): _________________________________

Business Name: ______________________________________________

NOTE:

Before leaving for appointment, phone to see that:

____________________________________________________________

electrical complete

Address: ____________________________________________________

water & drain complete (water-cooled)

City: ________________________________________________________

mix, cones, cups, syrup, etc. available

A

State:________ Zip: __________ Phone: ( ) __________________

trainee personnel available

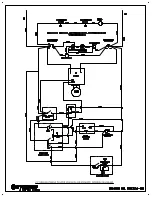

CHECK-OUT START-UP CHECKLIST (Each column represents a freezing cylinder)

1 2 3 4

(Check a column for each freezing cylinder)

Proper voltage, phase, breaker (check against nameplate)

Proper wire size per local code

High or unstable leg to L-2 (3-phase only)

Freezer level, front-to-back and side-to-side

Parts and accessories kit complete

1 2 3 4

Nuts, bolts, screws, electrical tight

Checked low pressure switch settings.

Drive belt tension/no lubricant leaks/check pulley and set screws

Locked thermostat settings.

Auger rotating counterclockwise

Water lines flushed before connection

(W/C)

Checked pressures on high side, suction side and barrel.

Proper water and drain size

(W/C)

Refrigeration level during operation (clear sight glass)

Proper clearance for air circulation

(A/C Remote)

Checked alignment

TRAINING CHECKLIST

Check off as completed:

Reviewed Owner's Manual with trainees.

Check for auger seal, bearing & flight wear each time the

Reviewed Operator's Safety Precautions in Owner's Manual

freezer is cleaned.

Reviewed Warranty Shown in Owner's Manual

Point out where Service Information Decal/Label is placed by

Disassemble, wash all parts, sanitize, lubricate & assemble.

the Distributor or Service Contractor.

Sanitize and start-up.

Key points: minimum mix level in hopper, etc.

Note:

Sanitizing must be done immediately before starting freezer.

Explain how foam in the hopper can prevent the low mix light

Check product temperature ___________ °F, overrun _____________

from illuminating.

Shutdown and cleaning procedure.

Discuss returning included survey if they choose.

LIST OF TRAINEES - Name of Trainees -

Training conducted by:

___________________________________________________

___________________________________________________

Name: _________________________________ Date: _____/_____/_____

___________________________________________________

Check one: Distributor Authorized Service Agency

SIGNATURE REQUIRED

Inspection/Checkout done by:

Inspection, check-out and operator training has been performed

on the above freezer. I have read and understand the warranty

Name: _________________________________ Date: _____/_____/_____

shown in the Owner's Manual.

Check one: Distributor Authorized Service Agency

x _________________________________________________

Signature, Buyer/Manager/Supervisor Date

Completed forms must be returned to Stoelting by mail, fax (800-545-0662), or email ([email protected]).

#236052 Rev. 1

IMPORTANT:

THIS SHEET MUST BE COMPLETED AND MAILED, FAXED, OR EMAILED WITHIN 30 DAYS

OF START-UP BY THE DISTRIBUTOR OR END-USER TO STOELTING IN ORDER TO REGISTER THE UNIT

UNDER WARRANTY. IF WE DO NOT RECEIVE IT, WE CANNOT PROCESS FUTURE WARRANTY CLAIMS.

B

Thi

s secti

on to be com

p

le

ted at i

n

stal

la

ti

on si

te.

Model No.

Serial No.

Thi

s secti

on to be com

p

le

ted before vi

si

ti

ng si

te.

Actual Settings 1 2 3 4

Supply Voltage

Head Pressure

Suction Pressure

Barrel Presssure

Содержание Stoelting CC101A

Страница 1: ...Model CC101A OPERATORS MANUAL Manual No 513616 Rev 6 ...

Страница 2: ......

Страница 14: ......

Страница 16: ...001 1332808 2 ...

Страница 26: ......

Страница 30: ......

Страница 32: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......