1800W MITER SAW ENG

TECHNICAL DATA

Note:

For power tool specifications refer to the nameplate on your power tool.

OPERATING INSTRUCTIONS

Note: Before using the power tool, read the instruction manual carefully.

1. Intended use

The machine is intended as a stationary machine for making straight lengthways and crossways cuts in

wood. Horizontal mitre angles of –52° to +52° as well as vertical bevel angles of 0° to 45° are possible.

The machine is designed with sufficient capacity for sawing hard and softwood as well as press and

particle board. The power tool is not suitable for cutting aluminium or other non-ferrous metals or alloys.

2. Unpacking

Due to modern mass production techniques, it is unlikely that your power tool is faulty or that a part is

missing. If you find anything wrong, do not operate the tool until the parts have been replaced or the

fault has been rectified. Failure to do so could result in serious personal injury.

1) Remove all loose parts from the carton.

2) Remove the packing materials from around the saw.

3) Using the carrying handle carefully lift the saw from the carton and place it on a level work surface.

4) The saw has been shipped with the saw arm locked in the down position. To release the saw arm,

push down on the top of the saw arm, pull on the release knob, rotate it 45° and let go, slowly raise the

saw arm.

Model

WD030210254

Voltage

110-120V AC

220-240V AC

Frequency

50-60Hz

50-60Hz

Power input

1800W

1800W

No load speed

5500/min

5500/min

Blade size

Ø 10” x Ø 1”

Ø 254 mm x Ø 25.4 mm

Mitre table angles

0° to 52° left & right

0° to 52° left & right

Bevel cuts

0° to 45° left

0° to 45° left

Straight cut

0° x 0°: 3 1/4” x 11 5/8”

0° x 0°: 81.5 mm x 295 mm

Mitre cut

45° (L&R) x 0°: 3 1/4” x8 1/16”

45° (L&R) x 0°: 81.5 mm x 205 mm

Bevel cut

0° x 45°(L): 1 5/8” x11 5/8”

0° x 45°(L): 43 mm x 295 mm

Compound mitre cut

45°(L) x 45°(L): 1 5/8” x 8 1/16”

45°(L) x 45°(L): 43 mm x 205 mm

Protection class

Machine weight

13.5Kg

13.5Kg

13

/

/

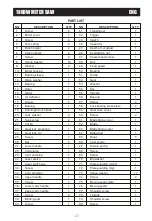

Содержание WD030210254

Страница 1: ...Miter saw WD030210254 1800W...

Страница 4: ...WD030210254 4 1 1 2 2 4 4 5 5 7 7 8 8 10 10 11 11 3 3 6 6 9 9 12 12 3 2 1 6 5 4 9 8 7 12 11 10...

Страница 7: ...WD030210254 7 37 13 38 14 41 17 43 19 44 20 40 16 16 39 15 42 18 45 21 39 38 37 42 41 40 45 44 43...

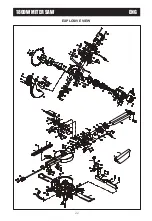

Страница 22: ...1800W MITER SAW ENG EXPLOSIVE VIEW 22...

Страница 26: ...26 WD030210254...

Страница 27: ...27 WD030210254...

Страница 28: ...MADE IN CHINA Copyright WIDO Machinery Co Ltd All rights reserved www widopt com...