1800W MITER SAW ENG

(See Fig 7).

Use the clamp assembly lock at the back of the fence to secure the clamp assembly in position (See

Fig 8).

10. Spindle lock button

The spindle lock button prevents the blade in the saw from rotating (See Fig 9). Depress and hold the

spindle lock button while installing, changing, or removing the blade.

11. Rotating lower blade guard

The rotating lower blade guard provides protection from both sides of the blade (See Fig 10). It retracts

over the upper blade guard as the saw is lowered into the workpiece.

12. Dust bag

The dust bag fits over the dust extraction port. For more efficient operation, empty the dust bag when it

is no more than half full. This allows better air flow through the bag (See Fig 11).

13. Attaching the side bars

The side support bars help to support the material when working with long workpieces. There are two

location holes for a support bar on either side of the table. Loosen the lock screws with the hex key.

Ensure the side bars are fully inserted before using them to support the workpiece (See Fig 12).

The side support bar locking screws must be tightened to secure the support bars in position (See Fig

13).

14. Trench depth adjustment

In its normal position, the trenching stop permits the saw blade to cut right through a workpiece. When

the saw arm is lifted, the trenching stop can be moved to the left so that the trenching depth adjustment

screw contacts the stop as the saw arm is lowered (See Fig 14).

This restricts the cut to a “trench” in the workpiece. The depth of the trench can be adjusted with the

trenching depth adjustment screw (See Fig 15) and locked in position with the trenching depth lock nut

(See Fig 16).

15. Turning on and off

1) Pull in switch trigger to start the unit (See Fig 17).

2) To turn the saw off release the on/off trigger switch.

16. Turning on the laser line generator

The laser line generator emits a single beam of pure red light to guide you as you cut. It improves

operator cutting vision, enables faster set-up, increases accuracy and improves safety. To turn on the

laser lines press the laser light on/off switch (See Fig 18). To turn off the laser press the laser light

on/off switch one more time.

17. Setting the table square with the blade

1) Make sure that the electrical plug is removed from the power point.

2) Push the saw arm down to its lowest position and engage the release knob to hold the saw arm in

the transport position.

15

Содержание WD030210254

Страница 1: ...Miter saw WD030210254 1800W...

Страница 4: ...WD030210254 4 1 1 2 2 4 4 5 5 7 7 8 8 10 10 11 11 3 3 6 6 9 9 12 12 3 2 1 6 5 4 9 8 7 12 11 10...

Страница 7: ...WD030210254 7 37 13 38 14 41 17 43 19 44 20 40 16 16 39 15 42 18 45 21 39 38 37 42 41 40 45 44 43...

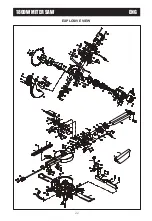

Страница 22: ...1800W MITER SAW ENG EXPLOSIVE VIEW 22...

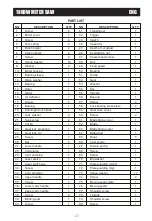

Страница 26: ...26 WD030210254...

Страница 27: ...27 WD030210254...

Страница 28: ...MADE IN CHINA Copyright WIDO Machinery Co Ltd All rights reserved www widopt com...