6

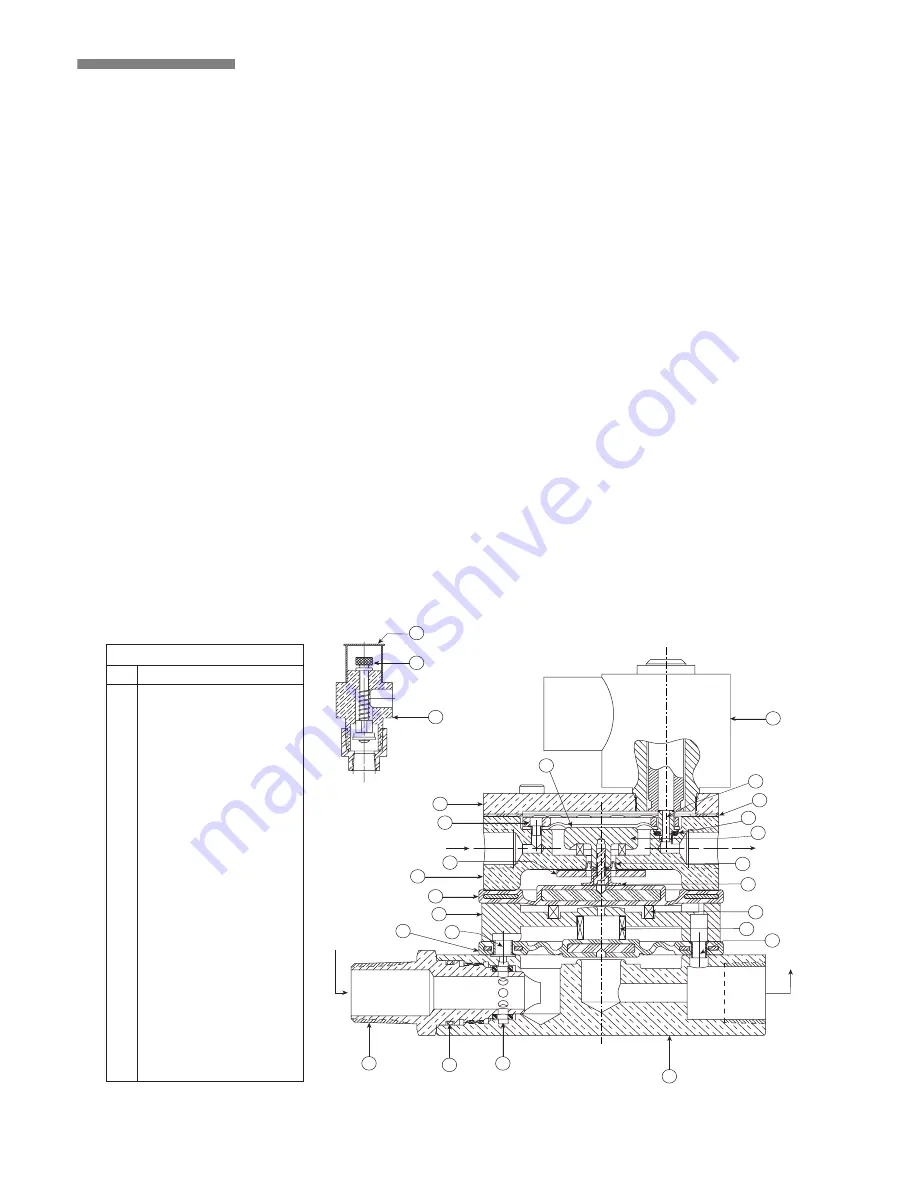

SECTION VIEW DRAWING AND DESCRIPTION –

SERIES 79N ELECTRIC/PNEUMATIC ACTUATOR

The Series 79N Electric/Pneumatic Actuator is a single-

unit device used in the actuation of Series 758 Preaction

Valves with double-interlock electric/pneumatic trim.

Diaphragms separate the Series 79N into four chambers.

The upper and upper-middle chambers control the

actuation, while the lower and lower-middle chambers

act as the water control valve.

During system charging, air pressure enters the upper-

middle chamber of the Series 79N. Pulling up on the auto

vent, which is located on the Series 79N trim, sets the air

pressure in this upper-middle chamber. Water supply

pressure from the piston charge line enters the upper

chamber, and the normally closed solenoid, which is built

into the Series 79N, sets this water pressure.

There is no

need to activate the solenoid in order to set the

system.

The system air pressure in the upper-middle chamber

exerts a closing force on the middle chamber of the Series

79N. Additionally, the water supply pressure from the

piston charge line exerts a closing force on the middle

diaphragm through a piston that connects the upper and

middle diaphragms. These pressures close the water path

of the lower-middle chamber.

When the piston charge line is open, water enters the

lower chamber of the Series 79N; this water flows to the

lower-middle chamber through the inlet. The middle

diaphragm traps water in the lower-middle chamber.

Supply water pressure in the upper chamber and system

air pressure in the upper-middle chamber hold the lower-

middle diaphragm assembly closed.

Since the area of the lower diaphragm is greater than the

area of the lower chamber, the lower chamber seals;

therefore, no water flows to the actuator’s outlet, and the

water pressure creates a seal.

When system air pressure decays to 6.5 psi (45 kPa), the

auto vent’s compression spring exerts a force greater than

the air pressure in the upper-middle chamber. The auto

vent opens, and all air pressure in the upper-middle

chamber evacuates. During this condition, the Series 79N

will not actuate, since the water pressure in the upper

chamber maintains a closing force on the water seal of

the lower-middle chamber.

Likewise, if there is an electrical detection event, the

solenoid on the upper chamber will activate and cause

the upper chamber’s water pressure to release. The Series

79N will not actuate, since the upper-middle chamber’s

air pressure exerts a closing force on the lower-middle

chamber’s water seal.

The Series 79N will actuate only when an electrical

detection and loss of system air pressure occur. During

this condition, the closing force on the lower-middle

diaphragm’s water seal is removed, and the lower-middle

chamber’s water pressure releases. This allows the lower

diaphragm to lift and water to flow from the Series 79N’s

inlet to the outlet. This water flow releases water pressure

from the preaction valve’s piston and allows the piston to

retract. The preaction valve’s clapper opens, and water

flows into the sprinkler system.

WATER IN

WATER IN

Located in the

trim of the

upper-middle chamber

TO DRAIN

TO DRAIN

1

16

26

14

12

13

11

3

25

21

19

18

17

20

4

24

23

22

15

5

7

8

9

10

6

2

1

Upper Chamber

2

Upper Diaphragm

3

Upper-Middle Chamber

4

Middle Diaphragm

5

Lower-Middle Chamber

6

Lower Diaphragm

7

Strainer Assembly

8

Strainer o-ring

9

Strainer Screen

10

Lower Chamber

11

Solenoid Valve

12

Auto Vent

13

Auto Vent Protective Cap

14

Auto Vent Knob

15

Outlet Orifice

16

Gasket

17

Upper Piston

18

Isolating Diaphragm

19

Lower Pison

20

Middle Spring

21

Lower Spring

22

Outlet Eyelet

23

Inlet Eyelet

24

Isolating Diaphragm Retainer

25

Upper Diaphragm Retainer

26

Outlet Orifice O-ring

BILL OF MATERIALS

Exaggerated for clarity

Item

Description

DISCONTINUED

PRODUCT