Chapter 2 Battery installation 15

LIEBERT APM UPS Module And Parallel System 30kVA~150kVA User Manual

Output System Connections

6. Connect the system output cables between the UPS output busbars (oA-oB-oC-N) and the critical load ensure

correct phase rotation. Tighten M6 Bolt to 5 Nm

Warning

If the load equipment will not be ready to accept power on the arrival of the commissioning engineer, then ensure that the system

output cables are safely isolated at their ends.

7. Re-install all the protective covers.

1.7 Control Cabling And Communication

1.7.1 Input and Output Interfaces

According to the specific needs of the field, the UPS may need auxiliary connection to realize the management of the

battery system (including external battery switch ad battery temperature sensor), communicate with PC, provide

alarm signal to external device, or realize remote EPO. These functions are realized through the UPS dry contact

located on the bypass module. The following interfaces are provided:

Back Feed Protection interface

External Battery Circuit Breaker interface

Battery ground fault detection

Battery temperature detection interface

Maintenance Bypass interface

Emergency Power Off interface

Service communication interface (for parameter setting and host monitoring)

Intellislots(TM) intelligent card interface

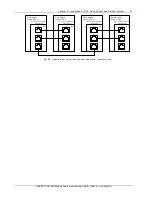

J8

J5

J10 J7

J6

J9

1

2

RS232

Intellislot 1

RS485

Intellislot 2

Intellislot 3

Fig.

1-4: Bypass Module (include Interfaces of dry contact and parallel signal board X2)

Note

All auxiliary cables must be double insulated twisted cables with cross sectional area of 0.5mm

2

~ 1.5mm

2

for maximum connection

length between 25m and 50m and must be routed separately from power cable

1.7.2 Back Feed Protection Interface (J5)

J5 is the backfeed protection interface, providing two relay output dry contact signals available to use with an

automatic device, externally located, to protect against back-feeding voltage thought the static bypass circuit.