22

PART 2 - User manual

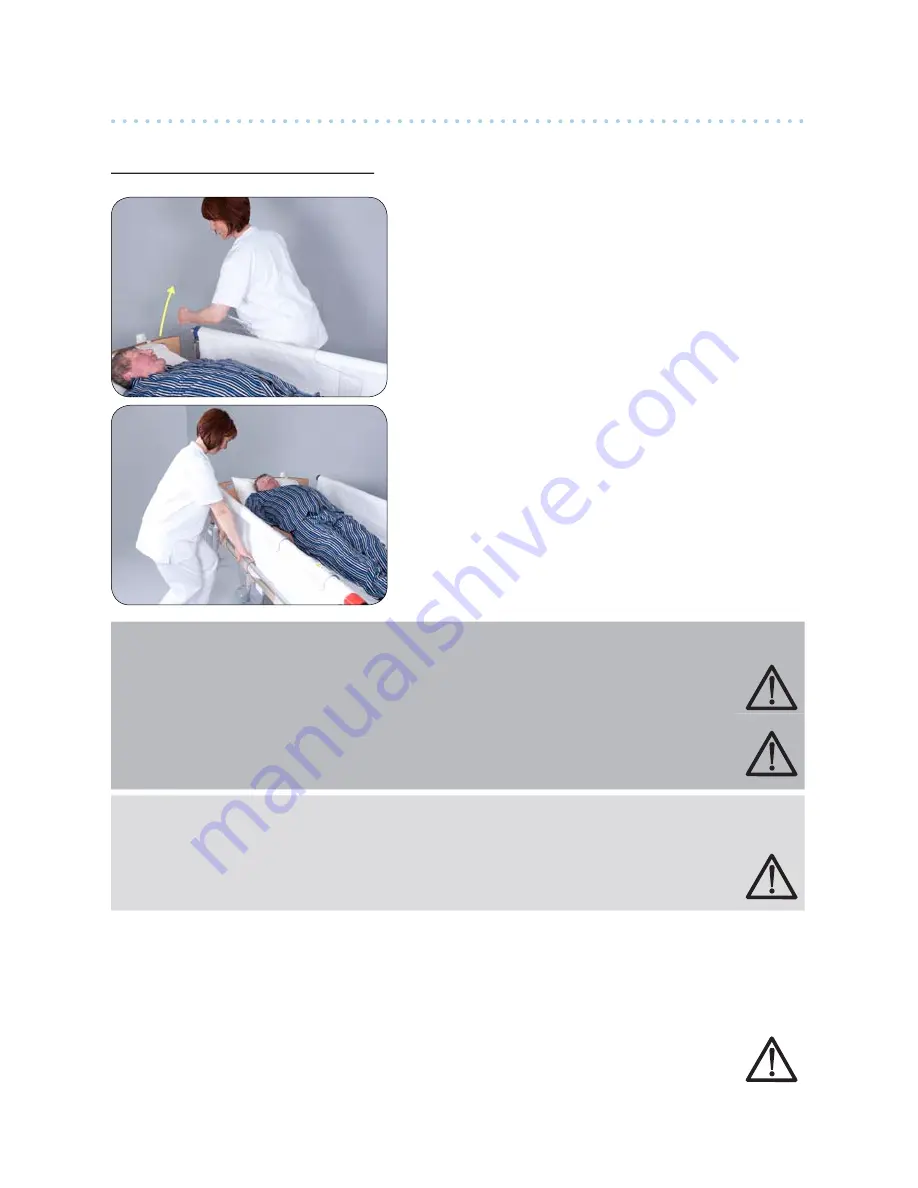

How to remove the plastic sides:

1. Adjust the height of the bed to ensure

correct work posture when the plastic

sides are removed from the bars.

2. Remove the plastic sides by grabbing them

by the side and pulling upwards, slightly

slanted.

3. The plastic sides may break if they get

caught. Consequently, plastic sides not in

use should always hang on the support

bar under the bars.

If the plastic sides are not used when the bars are raised, there is a risk that:

•

The gap between the headboard/footboard and the VENDLET will exceed 6

cm which could cause the patient to get pinned between the parts.

•

The distance between the bed frame and the lower edge of the bar will ex-

ceed 12 cm. This could cause the patient to fall through this opening, head or

feet first, with a risk of getting pinned between the parts.

If side rail support bars have not been mounted when the plastic sides are used, there is a

risk that:

•

The plastic sides will be pressed out, and the sheet will be rolled out which

could cause the patient to slide down onto the floor in the sheet.

Vendlet ApS shall not be liable if the plastic sides and support bars are not used on

beds with raised bars where patients are left unattended.

When the VENDLET system is not used as side rails

If the VENDLET system is not used as side rails, the bars must

be lowered when a patient is left unattended in the bed.