ins

ta

lla

tio

n

23

Värmebaronen EP- 900, -1080, -1200, -1400

Pipe installation

Excessive water flow can result in the following:

- Vibrations in the immersion heaters with noise and reduced

service life as a result.

- Unnecessary wear on the system's components.

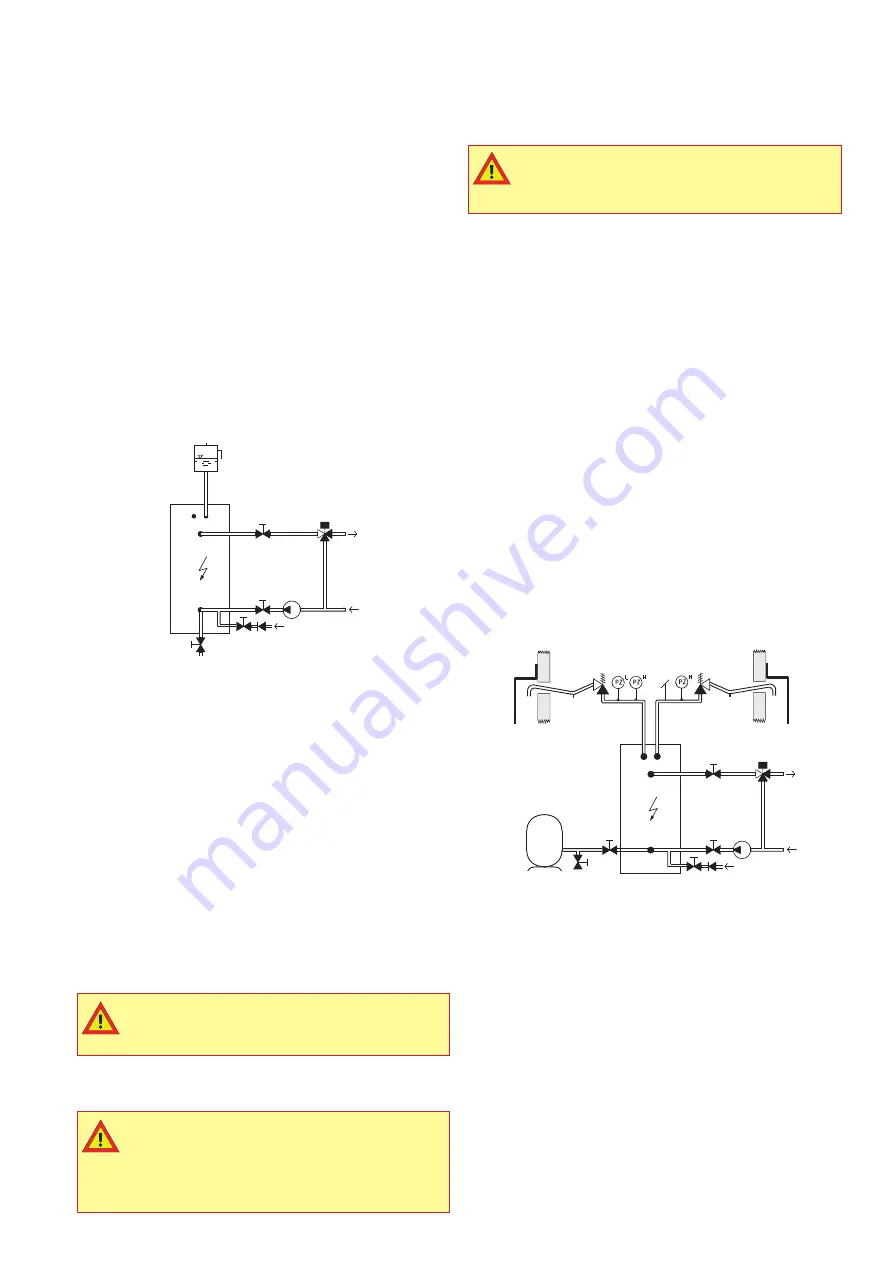

System principles

The figures shown are system principles. The actual system

must be installed according to existing standards.

Any additional equipment must be installed according to the

manufacturer's instructions.

Open system

The boiler's safety line must be connected in an uninterrupt-

ed, un-closeable pitch to an expansion vessel, installed at the

highest point of the heating system.

Expansion vessels are dimensioned to accommodate chang-

es in water volume due to heating and cooling.

Expansion vessels, safety pipes, aeration and overflow

pipes must be installed such that they are protected against

freezing.

To avoid oxygenation of the water, the distance between

the heating system’s highest point and the expansion vessel

must not be less than 2.5 metres.

Pressure height must exceed the pump's lowest static pres-

sure on the low side.

To avoid damage in the event of any blockage in

the expansion system, the boiler should be fitted

with a safety valve.

The air vent on the boiler's safety pipe must

always be open. Otherwise, air collects in the

top of the boiler, which leads to disruption as the

float switch is triggered on account of insufficient

water level.

Closed system without a expansion trap, >300 kW, ≤105ºC

The opening pressure of the safety valve is

determined by the component in the system that

tolerates the lowest pressure.

Under SS EN 12828, the installation must include:

- At least one safety valve min DN 15, with sufficient blow-off

capacity at the system's operating pressure.

- Two pressure guards, one with zero voltage release.

- Low pressure guard if there is a risk of boiling dry, alterna-

tive to level switch.

- Two temperature guards, STB.

- Flow guard if the boiler cannot cope with zero flow.

- Valve for expansion vessel, must be locked in open position.

- For boiler placed at a higher level than consumers, a level

guard is required

The boiler: - can cope with zero flow, from a safety viewpoint

- has two built-in temperature guards.

- has a built-in level sensor.

- can be supplied with factory installed safety

equipment.

Safety valves are fitted with pressure guards and an auto-

matic vent valve on the boiler's safety pipe.

The discharge pipe of the safety valve shall lead to a safe

place in accordance with the requirements of SS EN 12828.

Normally, this means on the outside of the building or in a

expansion trap.

The discharge pipe from the safety valve shall be dimen-

sioned so that the blow-off capacity is not impeded.

The discharge pipe must be laid so it cannot freeze, must be

cleaned well and must be laid so that water pockets cannot

form. DN 10 drainage must be provided if there is a risk of

standing water in the safety valve outlet line.