Wire Rope Safety Barrier

Wire Rope Safety Barrier

ASH LE

I N G A L C I V I L P R O D U C T S

ASH LE

I N G A L C I V I L P R O D U C T S

13

Release 07/22

MashFlex

Wire Rope Safety Barrier

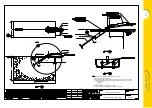

9. Ensure MashFlex cap is fully pushed down on post

and insert MashFlex Plug into hole on side of cap, the

plug is an interference fit and may require some light

force from a rubber mallet. Before inserting plug,

ensure the cable order is consistent and there are no

twists in the pattern, i.e. the third cable is consistently

in the third position for the entirety of the run. to the

two terminal posts (figures 15 and 16).

10. Insert the locking bolt into the cable anchor bracket,

refer figure 18.

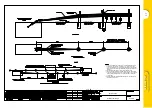

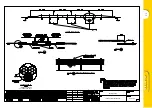

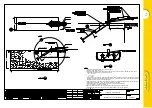

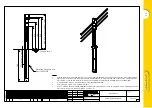

6.9 Installation of Tension Bays

Tension bays are located at 300m centres and not more

than 150m from either anchor point. This section is to be

read in conjunction with drawing WR-MF-059.

For fences less than 600m:

1. Swage the stainless steel end fittings onto all

the cables and attach to the anchor bracket. The

procedure for swaging is contained in the FlexFence

Swaging Unit Safe Operating Procedure Manual.

The bottom rope is located nearest to the approaching

traffic face. Each end fitting is secured at the anchor

with one washer and two nuts. If using the standard

terminal, ensure safety check ropes are attached

before swaging.

Note: An inspection hole is drilled into each stainless steel

end fitting to ensure the wire rope cables are properly

inserted into the end fittings before swaging.

2. Pull the slack out of the wire ropes toward the other

anchor. This can be achieved by hand or by using a

sling equipped with a lever claw clamp.

3. At locations where the wire rope reels have been

temporarily joined, swage the end fittings onto

the cables and install a tension fitting. End fittings

should be positioned so that the end of the fitting is

a minimum distance of 100mm from the post.

4. After the slack has been removed from the fence,

attach the check ropes (if required), machine swage

the end fittings and attach to the trailing or low-end

anchor.

5. Identify the tension bay location(s).

6. Mark and cut out an 800mm section from bottom,

second from bottom and top cables. Move past the

adjacent post and cut the 800mm section from the

third from bottom cable. This offsetting of the tension

bay for this cable will help expedite the tensioning

process. It may be necessary to attach temporary

clamps one post back from the tension bay location

prior to cutting in order to prevent the cables from

retracting. End fittings should be positioned so

that the end of the fitting is a minimum distance of

100mm from the post. Refer drawing WR-MF-059

and figure 19.

7. Swage the end fittings to each cable and attach

the tension fittings. The procedure for swaging

is contained in the FlexFence Swaging Unit Safe

Operating Procedure Manual.

8. Attach the tensioning rig to the bottom cable and

tension from the bottom up. The procedure for

Tensioning is contained in the FlexFence Tension

Unit Safe Operating Procedure Manual. Each rope is

tensioned in accordance with Table 5.

For fences greater than 600m:

1. Attach the safety check ropes (if required) and

machine swage the cables at the leading or high-

end anchor tand attach to the anchor bracket.

2. Pull the slack out of the wire ropes towards the 1st

tension bay location. This can be achieved by hand or

by using a sling equipped with a lever claw clamp.

3. At the 1st tension bay location clamp the wire

rope cable to a post. Repeat process for each cable,

clamping each cable to a different post.

4. Cut the cables on the un-tensioned side of clamps

and machine swage fittings. Assemble the tension

fittings.

5. Relocate to the 2nd tension bay and repeat the

above process. Continue until all the tension bays are

completed.

6. Once the slack has been removed from the fence,

attach the check ropes (if required), swage the end

fittings and attach to the trailing or low-end anchor.

7. Once the cables are attached at the anchor bracket,

relocate to the centre tension bay.

8. Attach the tensioning rig and tension in accordance

with Table 5 from the bottom up.

9. Relocate from the centre bay outwards repeating the

tension process.

10. Once complete, relocate to the centre bay and repeat

tensioning in this bay only.

Note:

Upon completion, the tension bays shall not be

more than 90% (40mm gap) of their full extent so as to

allow for further adjustment. There should also be a min

40mm exposed thread beyond each nut.

It is recommended that concrete used for the construction

of anchor blocks and post footings be cured for a period

of 7 days prior to tensioning.

Содержание INGAL MashFlex MASH TL3

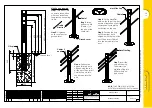

Страница 11: ...11 Release 07 22 MashFlex Wire Rope Safety Barrier Figure 10 Figure 11 Figure 12 Figure 13...

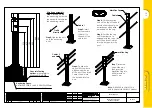

Страница 12: ...12 Release 07 22 MashFlex Wire Rope Safety Barrier Figure 14 Figure 15 Figure 16 Figure 17...

Страница 19: ...19 Release 07 22...

Страница 26: ...26 Release 07 22 Notes...

Страница 27: ...27 Release 07 22 Notes...