UNIBLOC-PD Operation & Service Manual: PD600-677 33

6.3 Torque Requirements & Special Tools

6.3.1 Torque Requirements

The following table lists torque settings. Contact Unibloc-Pump or an authorized service center for torque require

-

ments for applications with service pressures exceeding 21 bar (300 psig).

6.3.2 Special Tools

There are only a few special tools needed to assemble Unibloc PD600 Series pumps in a safe and secure way.

Please contact your pump supplier for ordering information.

PART

TOOL

(Size)

TORQUE SETTING

N·

m (ft·lb)

REAR ROTOR HOUSING STUD NUTS

WRENCH (30MM)

60 (44)

ROTOR BOLTS

(SINGLE-BOLT STYLE SHAFTS)

SOCKET W/ P.N. 6007-2 (17MM)

122 (90)

ROTOR BOLTS

(THREE-BOLT STYLE SHAFTS)

HEX KEY (10MM)

73 (54)

ROTOR LOCK NUT

(SINGLE-BOLT STYLE SHAFTS)

SOCKET (65MM)

434 (320)

FRONT COVER STUD NUTS

WRENCH (19MM)

50 (37)

BEARING HOUSING COVER BOLTS

SOCKET (17MM)

40 (30)

FRONT BEARING RETAINER RING BOLTS

SOCKET/ WRENCH (17MM)

50 (37)

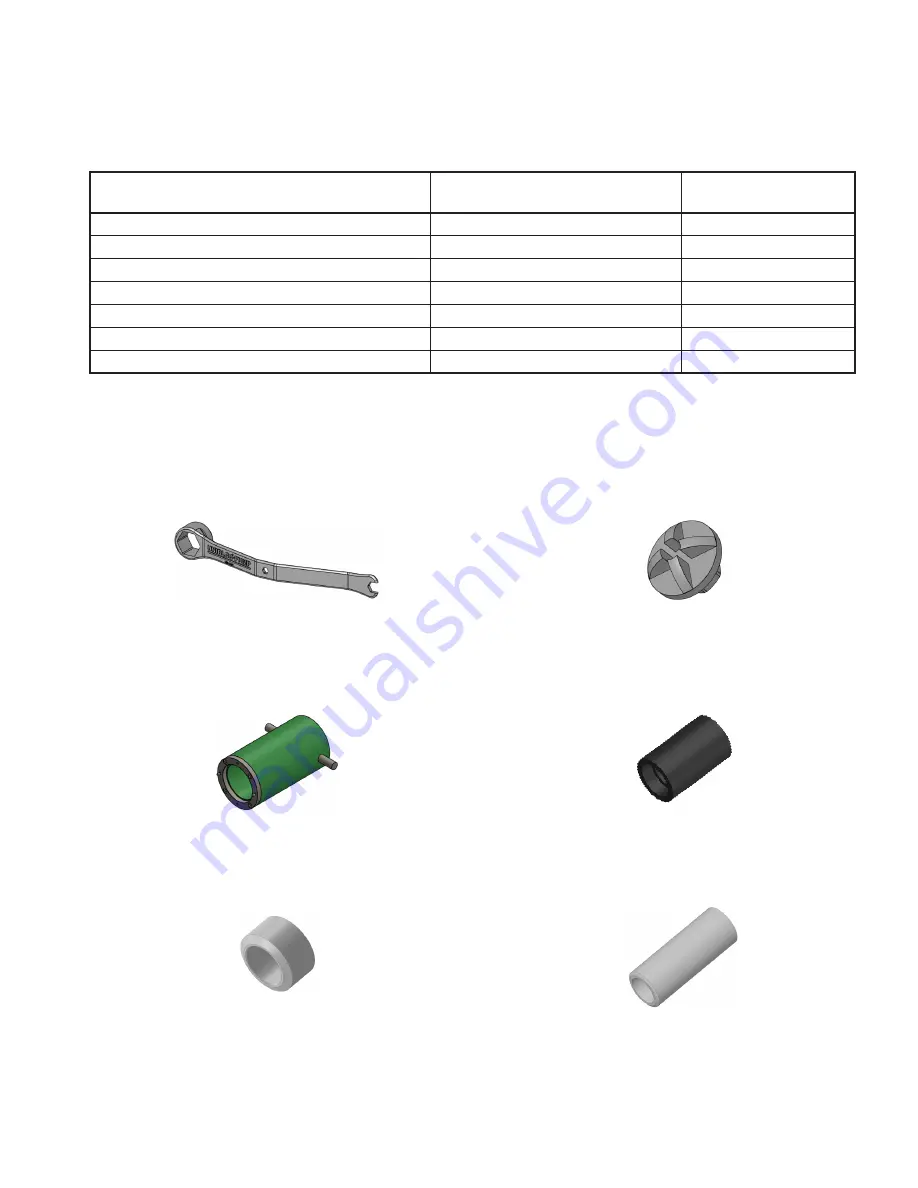

P.N. 6010-2

65mm Wrench for Single-Bolt style shafts

(PD602/652/677 Models Only)

P.N. 6007-2

Rotor Bolt Removal Tool

(PD602/652/677 Models Only)

P.N. 6011

Double O-Ring Seal Removal Tool

(PD602/652/677 Models Only)

P.N. 6012

Seal Installation Tool

(PD602/652/677 Models Only)

P.N. 6190B

Rear Bearing Assembly Sleeve

P.N. 6190A

Front Bearing Assembly Sleeve