UNIBLOC-PD Operation & Service Manual: PD600-677 21

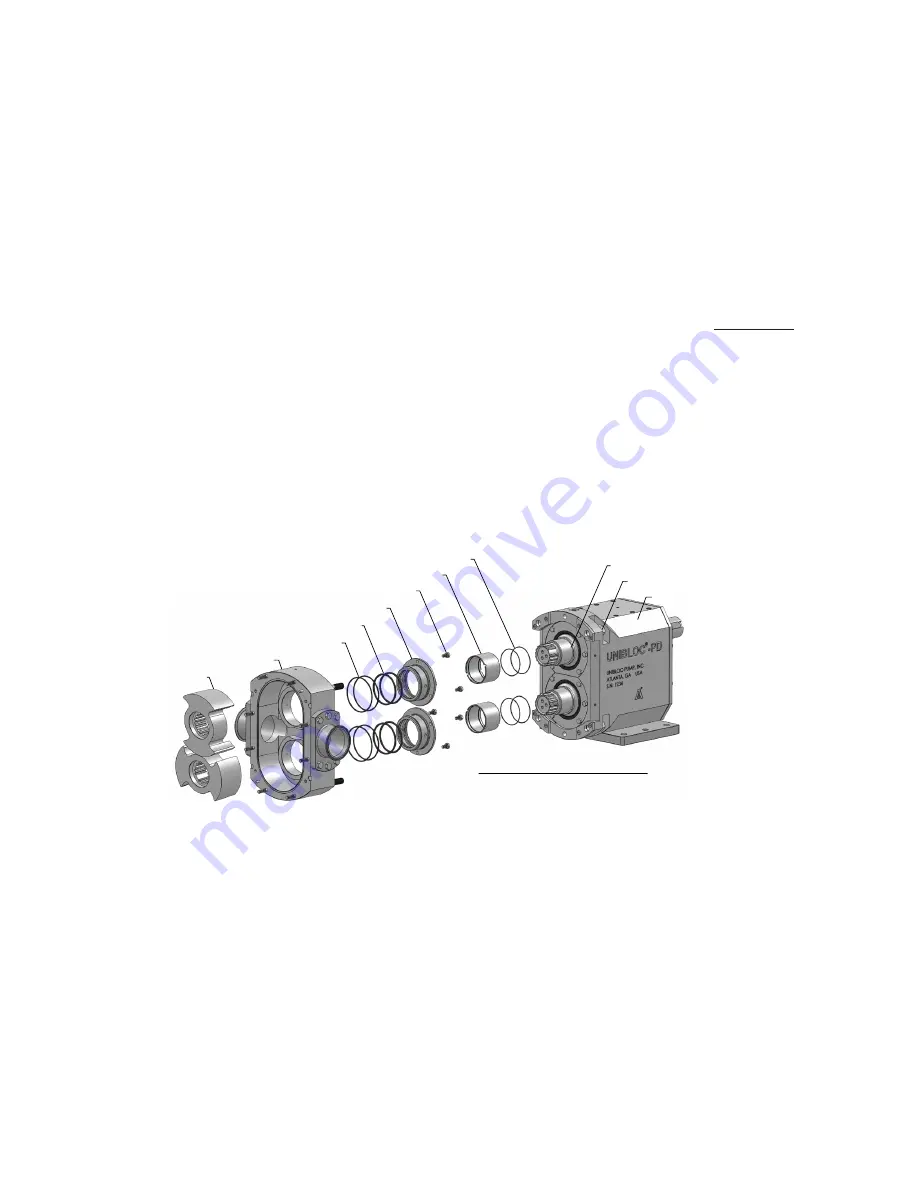

SEAL FLUSH HOUSING O-RINGS (INNER)

ROTOR HOUSING

ROTORS

SEAL FLUSH HOUSING O-RINGS (OUTER)

SEAL FLUSH HOUSINGS

WEAR SLEEVES

WEAR SLEEVE O-RINGS

ANTI-ROTATION PINS

SEAL FLUSH HOUSING BOLTS

BEARING HOUSING

FRONT VEW- ROTOR & BEARING HOUSING

REAR ROTOR HOUSING STUD NUTS

fig. 4.9

sleeve

6192B

(see section 6.3.2) over the splined end of the shaft and lubricate the surface of the mounting sleeve.

Place new

Seal Cartridge O-rings

into the grooves on the outside of the

Seal Cartridges

. Slide the

Seal Cartridge

on the mounting sleeve. Rotate the

Seal Cartridge

if necessary so that it will slide in the slots of the

Retainer Ring

.

Tap the

Seal Cartridge

into the

Rotor Housing

seal bore using mounting sleeve

6192A

(see section 6.3.2). When

properly installed the

Seal Cartridge

will bottom out against the

Retainer Ring

and will be flush or slightly below the

seal bore face. Remove the mounting sleeves and repeat for the other

Shaft.

Slide the

Rotors

on the

Shafts

. See

section 4.4.6 for completing the installation.

4.4.5 Double O-Ring Seal

This type of seal uses two o-rings to seal against a rotating shaft. It is most frequently used when the liquid viscosity

is greater than 2,000 cPs or is sticky. The maximum shaft rotational speed for this seal is 350 rpm and the maximum

service pressure should not exceed 8 bar (115 psig). This seal must never be allowed to run dry because the o-rings

will be damaged. It must be lubricated with grease or a flushing system as discussed in section 3.3. This seal also

uses the pumped product as a lubricant.

The rotor housing must be removed to service the rear loaded Double

O-Ring Seal on the PD600, PD650, and PD675 models.

4.4.5.1.1 Double O-Ring Seal Removal (REAR LOADED)- MODELS: PD600, PD650, PD675

(reference figs. 4.1, 4.9)

Slide the

Rotors

off the

Shafts

. If the rotors will not slide off they can be removed simultaneously with the

Rotor

Housing

. Unless they are being replaced,

DO NOT USE PLIERS OR CHANNEL LOCKS TO REMOVE THE RO-

TORS

.

THEY WILL BE DAMAGED.

To remove the

Rotor Housing

disconnect the flushing system, if applicable,

and loosen the

Rear Rotor Housing Stud Nuts

. Use a hoist and eye bolt to support the

Rotor Housing

. Tap on the

ports with a rubber mallet and pull the

Rotor Housing

off. Remove the

Seal Flush Housing Bolts

and slide out the

Seal Flush Housing

. Remove the

Seal Flush Housing O-rings (inner and outer)

. Slide off the

Wear Sleeves

and

remove the

Wear Sleeve O-rings

.

4.4.5.1.2 Double O-Ring Seal Installation (REAR LOADED)- MODELS: PD600, PD650, PD675

(reference figs. 4.1, 4.9, 4.15)

Clean all components prior to installing the seals. Check the

Wear Sleeves

for excessive wear. If grooves are notice

-

able, the sleeves may have to be replaced. Otherwise, the inner

Seal Flush Housing O-rings

may not seal properly

or may fail prematurely. Coat all surfaces that will have contact with o-rings with a lubricant approved for contact with

the pumped product. Place new

Seal Flush Housing O-rings (inner and outer)

into the grooves of the

Seal Flush

Housings

. Attach the

Seal Flush Housings

to the

Rotor Housing

with the

Seal Flush Housing Bolts

. Place new

Wear Sleeve O-rings

into the grooves of the

Wear Sleeves

. Slide the

Wear Sleeves

on the

Shafts

and locate on

the

Anti-Rotation Pins

. Using a lifting eye bolt, hoist the

Rotor Housing

on the

Dowel Pins

(see fig. 4.15 on pg.

24) and slide it on, while at the same time threading on the

Rear Rotor Housing Stud Nuts

. Tap the housing with a

rubber mallet to seat it properly against the

Bearing Housing

. Tighten the

Rear Rotor Housing Stud Nuts

in a cross

pattern. Slide the

Rotors

on the

Shafts

. See section 4.4.6 for completing the installation. It is imperative that the

cavity between

Seal Flush Housing O-rings (inner)

is filled with product compatible grease or the flushing system is

reconnected before operation is resumed.