35

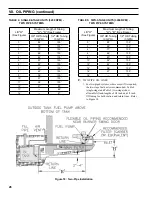

Figure 26: Intelligent Oil Boiler Control -

Horizontal mount Shown

IX. OPERATING

A.

WATER BOILERS SEQUENCE OF OPERATION

1.

Water Boilers Without Tankless Heaters

(Cold

Start), Sequence Of Operation:

a. The LEDV Boiler is equipped with an Intelligent

Oil Boiler Control (cold start boiler control).

The boiler control replaces the traditional

electronic aquastat and circulator relays and adds

energy saving thermal purge features. Energy is

saved by starting the circulator and delaying the

burner start when there is residual heat available

in the boiler.

b. The boiler’s sequence of operation is shown as

Status Codes on Boiler Control display. See

Table 8 and Figure 26.

Status Codes Displayed in

Mode

Status

Description

Standby

(burner off,

pump off)

No call for heat detected

Standby

(burner off,

pump on)

Either condition is true:

a. Call for heat detected and boiler

temperature higher than operating

setpoint.

b. Call for heat detected and boiler

temperature higher than 140 F and

Pump Pre-Purge Time has not

expired.

Running

The burner runs until the call for heat is

satisfied.

Self Test

Control internal checking

TABLE 8: SEqUENCE OF OPERATION

2.

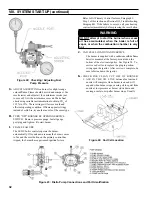

Using Boiler Control

The Boiler Control is located on front of boiler.

The Boiler Control display, along with Up

ñ

,

Down

ò

,

and

“

I

”

keys may be used to view boiler

operating status (Figure 27).

3.

Viewing the Operating Mode Options

In operating mode the user may view (but not

change) boiler operating status, settings and

troubleshooting information. To view Boiler

Control display information:

Figure 27: Boiler Control

Key Function & Orientation

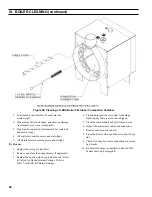

c. When the thermostat calls for heat the boiler

control starts the system circulator and the

thermal purge (circulator pre-purge time) begins.

If the time is completed or boiler temperature is

less than the Start Temperature (140 F default)

the start sequence continues by energizing the oil

primary to operate the following sequence:

blower is started and operates for pre-purge time;

spark is energized and fuel valve is opened for

ignition trial time; burner fires until the

thermostat is satisfied.

d. If the thermostat is not satisfied and the Operat

-

ing Setpoint (SP) is reached the system circulator

will continue to operate and the burner will stop.

When the boiler water temperature drops below

the setpoint less the differential setting the burner

will restart.

e. After the thermostat is satisfied the burner and

circulator are stopped.

f. When an indirect water heater aquastat call for

heat is wired to the “ZR” terminal the Boiler

Control starts a domestic hot water circulator

connected to the “ZC” terminal and when the

boiler temperature is less than Operating Setpoint

(SP), the boiler control energizes the oil primary

to turn on the burner without circulator pre-purge

delay.

g. On burner start, if the CAD cell does not see

flame within approximately 15 seconds, primary

control will shut down the burner and enter into a

lockout mode. A lockout is reset by pressing the

reset button located on the primary control. If

the flame is lost while the burner is firing, the

primary control shuts down the burner, enters a

60 second recycle delay, and repeats the ignition

sequence. If after three (3) trials for ignition,

flame is not detected, primary control will enter

into restricted mode. Restricted mode is reset by

holding down the reset button for 15 seconds.

Содержание LE DV Series

Страница 5: ...5 I General Information Figure 1A LEDV Packaged Water Boiler with Beckett AFII Burner ...

Страница 6: ...6 I General Information continued Figure 1B LEDV Packaged Water Boiler with Riello BF Burner ...

Страница 19: ...19 v venting continued Figure 11 Vent Installation Figure 12 Vent Connector Un Assembled ...

Страница 20: ...20 v venting continued Figure 13 Vent Connector Assembled Figure 14 Air Intake Installation ...

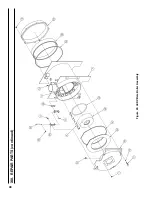

Страница 48: ...48 xiii Repair Parts continued Figure 29 LEDV Bare Boiler Assembly ...

Страница 50: ...50 xiii Repair Parts continued Figure 30 LEDV Boiler Jacket Insulation ...

Страница 55: ...55 xiii Repair Parts continued Figure 33 Vent Kit Repair Parts ...

Страница 60: ...60 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net ...