3

DANGER

DO NOT store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

personal injury or loss of life. Failure to follow all instructions in the proper order can cause personal

injury or death. Read and understand all instructions, including all those contained in component

manufacturers manuals which are provided with the boiler before installing, starting-up, operating,

maintaining or servicing this boiler. Keep this manual and literature in legible condition and posted

near boiler for reference by owner and service technician.

This boiler requires regular maintenance and service to operate safely. Follow the instructions

contained in this manual.

Installation, maintenance, and service must be performed only by an experienced, skilled and

knowledgeable installer or service agency.

All heating systems should be designed by competent contractors and only persons knowledgeable in

the layout and installation of hydronic heating systems should attempt installation of any boiler.

Installation is NOT complete unless a pressure relief valve is installed into the 3/4" tapping located on

top of Shell Assembly, see Figures 1A and 1B. Also see Water Piping and Trim Section of this manual

for additional details.

It is the responsibility of the installing contractor to see that all controls are correctly installed and

are operating properly when installation is complete including verifying that the limit sensor is fully

installed (seated in bottom of Well).

Failure to properly install Limit Sensor may result in property damage, personal injury or loss of life

due to elevated operating temperatures and/or pressures.

This boiler is suitable for installation on combustible flooring.

DO NOT install boiler on carpeting.

DO NOT tamper with or alter the boiler or controls.

Retain your contractor or a competent serviceman to assure that the unit is properly adjusted and

maintained.

Have Firetubes cleaned at least once a year - preferably at the start of the heating season to remove

soot and scale. The inside of combustion chamber should also be cleaned and inspected at the same

time.

When cleaning this boiler, DO NOT damage combustion chamber. If damaged, combustion chamber

must be replaced immediately.

Oil Burner and Controls must be checked at least once a year or as may be necessitated.

DO NOT operate boiler with jumpered or absent controls or safety devices.

DO NOT operate boiler if any control, switch, component, or device has been subject to water.

Boiler materials of construction, products of combustion and the fuel contain alumina, silica, heavy

metals, carbon monoxide, nitrogen oxides, aldehydes and/or other toxic or harmful substances which

can cause death or serious injury and which are known to the state of California to cause cancer, birth

defects and other reproductive harm. Always use proper safety clothing, respirators and equipment

when servicing or working nearby the boiler.

Содержание LE DV Series

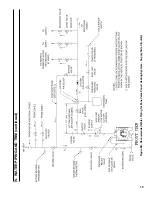

Страница 5: ...5 I General Information Figure 1A LEDV Packaged Water Boiler with Beckett AFII Burner ...

Страница 6: ...6 I General Information continued Figure 1B LEDV Packaged Water Boiler with Riello BF Burner ...

Страница 19: ...19 v venting continued Figure 11 Vent Installation Figure 12 Vent Connector Un Assembled ...

Страница 20: ...20 v venting continued Figure 13 Vent Connector Assembled Figure 14 Air Intake Installation ...

Страница 48: ...48 xiii Repair Parts continued Figure 29 LEDV Bare Boiler Assembly ...

Страница 50: ...50 xiii Repair Parts continued Figure 30 LEDV Boiler Jacket Insulation ...

Страница 55: ...55 xiii Repair Parts continued Figure 33 Vent Kit Repair Parts ...

Страница 60: ...60 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net ...