SARA-G3 series - System Integration Manual

UBX-13000995 - R06

Objective Specification

Design-in

Page 113 of 218

o

Select an integrated antenna solution provided by an antenna manufacturer if the required

ground plane dimensions are large enough according to the related integrated antenna solution

specifications: the antenna selection and the definition of its placement in the product layout

should begin at the start of the product design process

o

It is highly recommended to strictly follow the detailed and specific guidelines provided by the

antenna manufacturer regarding correct installation and deployment of the antenna system,

including PCB layout and matching circuitry

o

Further to the custom PCB and product restrictions, the antenna may require a tuning to

comply with all the applicable required certification schemes. It is recommended to ask the

antenna manufacturer for the design-in guidelines for the antenna related to the custom

application

In both cases, selecting an external or an internal antenna, observe these recommendations:

Select an antenna providing optimal return loss (or V.S.W.R.) figure over all the operating

frequencies

Select an antenna providing optimal efficiency figure over all the operating frequencies

Select an antenna providing appropriate gain figure (i.e. combined antenna directivity and efficiency

figure) so that the electromagnetic field radiation intensity do not exceed the regulatory limits specified

in some countries (e.g. by FCC in the United States, as reported in section 4.2.2)

For the additional specific guidelines for SARA-G350 ATEX modules integration in potentially

explosive atmospheres applications, refer to section 2.13.

2.3.1.2

Guidelines for antenna RF interface design

Guidelines for ANT pin RF connection design

Proper transition between the

ANT

pad and the application board PCB must be provided, implementing the

following design-in guidelines for the layout of the application PCB close to the

ANT

pad:

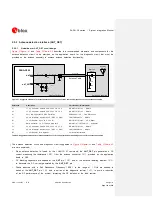

On a multi layer board, the whole layer stack below the RF connection should be free of digital lines

Increase GND keep-out (i.e. clearance, a void area) around the

ANT

pad, on the top layer of the

application PCB, to at least 250 µm up to adjacent pads metal definition and up to 400 µm on the

area below the module, to reduce parasitic capacitance to ground, as described in the left picture in

Add GND keep-out (i.e. clearance, a void area) on the buried metal layer below the

ANT

pad if

the top-layer to buried layer dielectric thickness is below 200 µm, to reduce parasitic capacitance to

ground, as described in the right picture in