409-10016

ELT Machine 1338600-[ ]

Rev H

9 of 34

Tyco Electronics Corporation

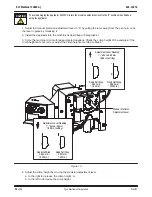

2.3. Machine Guard

(Figure 8)

A guard is installed to provide protection for the operator while maintaining proper visibility of the work area.

The guard swings open to allow easy access for applicator installation and setup. A safety interlock on the

guard prevents the machine from cycling if the guard door is open during production operation.

Machine -4 does not include the safety interlockfeature. To avoid personal injury, remember that the power is not

automatically shut off when the guard doors are opened.

Figure 8

Machine

Guard

Shown with Safety Interlock

(Not on Machine -4)

Hole for Customer

Supplied Lift Ring

Quick-Release T-Handle

for Machines -1, -2, -5,

and -6

Shown with Optional

Precision Crimp Height

Adjustment Mechanism

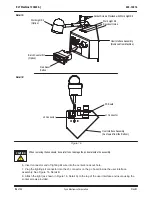

3. RECEIVING INSPECTION AND INSTALLATION

3.1. Receiving Inspection

ELT machines are thoroughly inspected during and after assembly. A final series of inspections is made to

insure the proper machine functioning before packaging and shipping.

To protect against damage that may have occurred during shipment, remove the machine from the crate

(Paragraph 3.2) and carefully inspect the machine for damage. If damage is evident, file a claim against the

carrier and notify Tyco Electronics immediately.

3.2. Installation

Remove all mounting bolts securing the machine to the shipping pallet. Install lift ring (see Figure 8) on top of

the machine.

Lift ring (M1220 eye bolt) is customer supplied.

DANGER

NOTE

i