409-10016

ELT Machine 1338600-[

Rev H

16 of 34

Tyco Electronics Corporation

the position of the speed control knob. The new speed setting will remain active for a maximum of three

seconds after the Jog button is released, or until the crankshaft completes the cycle. If the cycle is not

complete and the Jog button is again pressed within three seconds from its release, the crankshaft will

rotate at the speed defined by the position of the speed control knob. Failure to push the Jog button within

the three seconds of its release will cause the crankshaft jog speed to revert back to the initial minimum

default value. After the Jog button is released, the speed control knob can be rotated in either direction to

increase or reduce the crankshaft jog speed, but Jog button must be activated again within three seconds

of the release or the speed will revert back to minimum default speed. The speed control knob can be

reset as many times as desired.

The machine will exit the Jog (With Guards Disabled) Mode whenever the guards are closed or the power

is turned “off.”

The speed control knob in Figure 10 also adjusts the air feed timing. Normally the air feed timing is set at 280 ms.

When the speed control is set at less than 50% of its maximum setting (pointing straight down or counterclockwise

from pointing straight down), the air feed timing changes to 440 ms. This is done to accommodate applicators that

have longer than normal air cylinders.

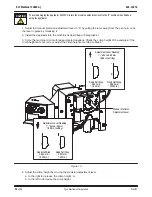

The green flashing status indicator flashes a specific number of times to represent a corresponding fault. For

example, the green status indicator will flash two times (each followed by a one second pause) to indicate that

the machine guard opened while the machine was running. Refer to Figure 11.

FAULT INDICATOR CODE

(Number of Consecutive Flashes)

ELT MACHINE FAULT

2

Theguard opened whilethemotor was running.

3

The guard must be closed before proceeding.

4

Motion from top dead center (TDC) was not detected.

5

The TDC switch was not sensed.

6

A bad PWM IGBT was detected.

7

A bad Jog push button input was detected.

8

A bad footswitch input was detected.

9

A bad DC bus relay was detected.

10

A bad jog enable input was detected.

11

Thelinevoltageis not within specifications.

12

A bad spare input was detected.

Figure 11

4.5. Crimp Height Adjustment

On ELT machines that do not include the precision adjustment feature, the crimp height must be adjusted at

the applicator. Refer to the instructions provided with the applicator to perform this adjustment. Refer to

Paragraph 6.3 for procedures to adjust the crimp height using the ELT machine precision adjustment feature.

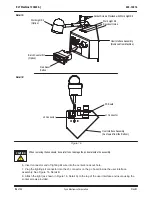

4.6. End-Feed/Side-Feed Applicator Conversion

When changing from an end–feed applicator to a side–feed applicator (or from a side–feed applicator to an

end–feed applicator), the reel support assembly must be moved to the opposite side of the machine. With the

terminal reel removed, lift and rotate the reel support bar to the opposite side of the machine. Mount the

terminal reel on the reel support and load the terminal strip into the applicator. Remove the metal terminal

lead–in and thumbscrews and move to the opposite side of the machine. Move the machine lubricator bowl to

the opposite side of the machine as required.

Lubricator Bowl Assembly 354550-1 is an optional accessory.

NOTE

i

NOTE

i