8

Calibration

CAUTION!

Disconnect the motor wires to prevent accidental spin up.

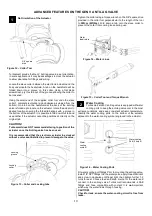

To calibrate the electronic Anti lag valve, the cap must be

removed to allow access to the manual override screw. Please

note that the valve seat must be in place before calibration.

Using an Allen key remove the 2 top bolts allowing the cap to be

removed, and a spacer or shift the cap off to one side and reinsert

at least one of the bolts. This prevents the preload in the

mechanism separating the housing potentially effecting the

calibration accuracy.

Figure 9

– Top Cap removed for calibration

Carefully move the motor wired allowing access to the manual

override below (Figure 12)

Figure 10

– Manual Override

Using a ¼” drive extension with a 5mm socket, turn the manual

override in a clockwise direction with your fingers until the

mechanism stops rotating. In this position the valve should be

home against the valve seat and will be your 0% position.

Remember to have the valve seat inserted.

CAUTION!

Do not apply excessive force to the manual override, doing

so will damage the product and effect the performance.

Figure 11

– ¼ Drive extension with 5mm socket manually

adjusting.

Using your ECU manager software, read the voltage from the

sensor and set this as your closed position.

Wind the manual adjustment in an anticlockwise direction until it

stops. From this position rotate the adjustment 2 full turns in a

clockwise direction. Read the sensor value and set this as 100%

valve travel.

Monitor sensor signal voltage to ensure no wrap around occurs

throughout the stroke of the valve that could affect operation.

CAUTION!

It is critical not to set the 100% position at the end of the

travel as this may lead to seizing of the anti-lag valve and

overloading the system.

NOTE!

Turbosmart recommends allowing additional clearance

from the end stops until the Anti lag valve control is tuned

to minimise risk of overshoot into end stops at high speeds.

Tuning

The anti-lag valve will come calibrated from Turbosmart,

the targeted values have been set with regards to the position

sensor are 0.5V (completely open) and 4.5V as (completely

closed), It’s important to note that as the anti-lag valve moves

through its range of motion that the valves are monitored to move

from 4.5V decreasing to 0.5V, 0% open to 100% open. This

should be done manually with the ECU package monitoring

Voltage Values. The electronic motor should be disconnected at

this point.

Voltage wraps around will cause errors with the Anti lag valve,

this is when the Voltage increases from 4.8V up to 5V and jumps

through to 0V.

Position Sensor

Target Voltage

Duty Cycle

100%

0.20-0.60V

~16%

0%

4.40-4.80V

~84%

It is important to set up the correct limits manually with anti-lag

valve. Turbosmart recommends that the valve is only ever

driven electronically to the maximum valve position of 90

%.

4

3

Cap retaining

bolts

Manual

Override

Valve Down

Valve UP

5