7

the Anti Lag Valve is home correctly while torqueing the nut to

not have a false torque as this will likely contribute to exhaust

leaks. Ensure O-Ring is in place on the inlet compressed air side

of the valve.

Connecting Your Anti lag valve

The Turbosmart Electronic Anti-lag valve comes

unterminated with 6, or 7 wires. A revision was made to include

the additional (Blue) wire for internal / development only

purposes.

Revision A

can be identified by its total of 6 wire

count, while

Revision B

can be identified by its total wire count

of 7.

Revision B (current)

– Wiring

Colour

Description

1 single core

wire each

Large Gauge Red

Motor A tending towards

0%

Large Gauge

Black

Motor B tending towards

100%

Multi Core

Wire

Red

5V

Black

Sensor ground 0V

White

Position Signal 0-5V

Blue

(Rev B Only)

*

Unfiltered

Signal (Position Output)

Yellow

(Orange

Rev A)

Temperature Signal 0-5V

*Note: The Blue (unfiltered position signal) is not required

for use & is for development purposes only.

Sensor Voltage Limits

Deg C (Deg F)

Temperature

Sensor

Output (mV) Rev A

Temperature

Sensor

Output (mV) Rev B

0 (32)

500

2630

150 (302)

2000

538

Position Sensor

Target Voltage (V)

Duty Cycle (Rev B

only)

100%

0.20-0.60V

~16%

0%

4.40-4.80V

~84%

CAUTION!

Turbosmart recommends calibrating the position sensor

before connecting the motor wires to your motor drive.

The two large wires are directly connected to the motor of the

anti-lag valve and need to be connected to high power drives in

a Full bridge configuration like that of an electronic throttle drive

circuit, see your ECU supplier documents for suitable

connections. Turbosmart recommends the anti-lag valve should

be driven by an External dual H-Bridge, that is at least 20A for

seamless operation.

Connect the small Red Wire to a 5V power source from your ECU

as well as the Black wire to Sensor ground. Connect the white

wire to a 0-5V analogue input on your ecu as well as the orange

temperature sensor signal. The blue wire (Revision B only) is an

unfiltered position output signal for development purposes - This

can be left unterminated.

CAUTION!

Whilst the temperature sensor is not required for operation,

it is recommended for activating failsafe protocols.

CAUTION!

Ensure all connections are high quality and away from any

heat source.

CAUTION!

It is important during the setup of the eGate, that some

precautions are taken to ensure that the unit does not

malfunction. Firstly, the output from the ECU should be

limited to 15%. As well as an inline fuse (5A-10A) or breaker

to protect the eGate. Once correct operation has been

verified the fuse and limits can be removed.

3

3

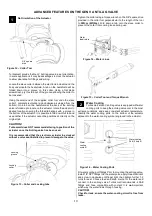

Figure 7

– Vee Band Clamp

Figure 8

– Exploded Drawing