10

ADVANCED FEATURES ON THE GEN V ANTI LAG VALVE

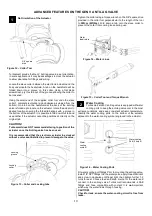

Re-Orientation of the Actuator

Turbosmart provide the Gen V Anti lag valve in a set orientation,

in some applications it may be advantages to clock the actuator

to allow clearance for fittings and wiring.

Locate the slave collar between the electronic actuator and the

body underneath the heatshield, A tab on the heatshield will be

folded down into a groove on this collar. Using a flat blade

screwdriver, pry this tab out of the groove allowing the collar to

be loosened.

Using the small end of the supplied collar tool undo the slave

collar 1 complete revolution (anti-clockwise as viewed from the

bottom). One tab on the heatshield at the back of the anti-lag

valve is folded up to locate on the actuator, rotate the actuator to

desired location ensuring the folded tab aligns with a groove in

the bottom of the actuator. It is possible to fold down this tab and

use another if the actuator cannot be positioned correctly on the

original tab.

CAUTION!

Turbosmart does NOT recommend altering to position of the

actuator once the Anti lag valve has been used.

It is recommended that the electronic actuator be clocked

without a valve seat installed to prevent damage to the valve.

Tighten the collar using a torque wrench on the 3/8” square drive

provided in the collar tool perpendicular to the length of the tool

to

30N.m (22ft/lbs).

Fold down a tab onto the slave collar to

prevent the collar from coming loose during use.

Water Cooling

Turbosmart’s Gen V anti lag valve is equipped with water

cooling ports to keep the anti-lag valve cool in the most

extreme conditions and keep consistent actuator temperature.

Identify the water cooling ports on the bottom of the actuator

adjacent to the water-cooling symbol engraved in the actuator.

Fit water-cooling port fittings Prior to mounting the anti-lag valve,

install 1/8” NPT fittings into the water ports, apply thread lubricant

and screw in clockwise until finger tight, then tighten further 1-2

turns for seal. Choose feed and drain source for the water and

connect to the anti-lag valve. Turbosmart recommends -4SAE

fittings and hose compatible with coolant. It is

not

important

which way the water flows through housing.

CAUTION!

Check for leak, ensure the water-cooling circuit is free from

leaks.

Water cooling

Port (2 holes)

1

3

2

3

Water

cooling

symbol

Locking

collar

Locking

groove

3/8” square

drive

Water

feed/return

Figure 12

– Collar Tool

Figure 14

– Water Lines

Figure 15

– Collar Tool and Torque Wrench

Figure 13

– Collar and Locking tabs

Figure 16

– Water Cooling Ports