6

GEN V ALV Accessories

TS-0550-3114

ALS 6-1 Weld flange

(for 6 cylinder/V12/6 outlet pipes)

TS-0550-3104

ALS 5-1 Weld flange

(for 5 cylinder/V10/5outlet pipes)

TS-0550-3098

ALS 4-1 Weld flange

(for 4 cylinder/V8/4 outlet pipes)

TS-0550-3099

ALS 3-1 Weld flange

(for 3 cylinder/V6/3 outlet pipes)

TS-0550-3100

ALS 2-1 Weld flange

(for 2 cylinder/2 outlet pipes)

TS-0505-3001

WG40 Inlet Weld Flange

(for single outlet)

TS-0550-3101

Inlet Weld Flange AL

TS-0550-3102

Inlet pipe adapter 1-3/4" OD

TS-0550-3103

Inlet pipe adapter 1-1/2" OD

TS-0552-3001

WG40 Valve Seat

TS-0552-3003

WG40 Inlet/WG45 Outlet V-Band

TS-0552-3004

WG40 Outlet V-Band

TS-0550-3076

WG40 weld purge bung

TS-0550-3080

V-Band Replacement Nut - 2 Pack

TS-0550-3009

WG38/40 Actuator Collar

FITTING YOUR GEN V ALV

Mounting your New Turbosmart Gen V ALV

(Anti Lag Valve)

The weld flanges should be welded to your exhaust system. The

weld flanges are compatible with stainless steel and mild steel

welding rod material.

For best results tubes should be plumbed into the turbo manifold

as close to the exhaust port of the engine for maximum efficiency.

Turbosmart Weld flanges are designed to accept 19mm (3/4”)

tube, large diameter tubes with the least amount of restriction will

achieve a higher amount of usable energy in the manifold.

CAUTION!

Do not place the actuator cap near a significant heat source

as this could shorten the life of the diaphragm.

CAUTION!

Use of the Antilag valve produces excessive heat in the

exhaust manifold and turbo and may result in shorter than

expected life.

Plumbing the antilag valve into the exhaust port maximises the

thermal energy from the exhaust to increase the flame front with

fresh air and unburnt fuel.

Connect the inlet of the ALV to the charge intercooler piping pre-

throttle body, having the pipe, and attached at an angle in the

direction of flow may help the efficiency of the system.

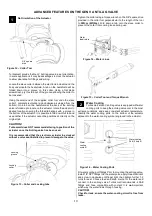

Fitting the Gen V ALV

Prior to mounting the Gen V ALV, place v-band over weld on

flange by unscrewing the nut on the v-band as far out as possible

and then squeezing the bolt in a syringe motion to expand the v-

band (squeeze the dots together below). Once the v-band is in

its fully expanded position, slide the v-band over the flange to

allow for the ALV to be installed.

Do not forget to put the valve seat into the body before mounting

the unit on the exhaust manifold.

Using the 3/8” deep socket and

a torque wrench Tighten the V-Band to 7N.m (5 ft/lbs). Ensure

1

2

3

eALV

ALV

Runners

Turbo

Flange

Turbo pressure

source

ALV

Turbo

Turbo Compressor

housing

Figure 5

– ALV mounted on Exhaust Manifold

Figure 6

– ALV mounted on Turbo system