3

TOOLS REQUIRED

-

¼” drive socket 5mm

-

¼” drive extension

-

¼” drive ratchet

-

3/8” square drive deep socket

- Square drive ratchet wrench

-

Torque wrench (3/8” drive)

- Non-marking spanners to tighten fittings

- Supplied collar tool

SUGGESTED LUBRICANTS AND

SEALANTS

- Loctite 243 Thread locker

- Loctite 567 Thread Sealant

- Resbond 907TS Red

- Penetrating oil

- Inox MX8 spray grease

PART NUMBERS

TS-0552-1601

– GenV eALV40 Electronic Anti-Lag Valve Black

------------------------------------------------------------------------------------------------------------------------

QUICK START GUIDE

CAUTION!

It is important during the setup of the eGate, that some precautions are taken to ensure that the unit does not malfunction.

Firstly, the output from the ECU should be limited to 15%. As well as an inline fuse (5A-10A) or breaker to protect the eGate.

Once correct operation has been verified the fuse and limits can be removed.

HOW TO USE

The Turbosmart anti lag valve is a brand-new way to drive aftermarket Anti lag valve valves, it involves using an electric

motor to drive the position of the valve, this allows far greater control over the valve during its actuation on the car, this

paired with an aftermarket ECU controlling it, allows for plenty of new and safer ways to anti lag strategies on your car.

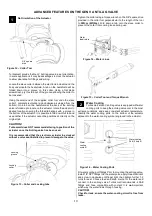

The Body will need to be fitted to the vehicle.

Please see the exploded drawing.

This involves the two V Bands clamps,

the outlet (fitted on the exhaust manifold), and the inlet where the diverted boost pressure is fed into the exhaust. A Valve

seat is fitted inside the outlet V Band allowing the valve to seal upon closing. It is important to have the valve manually set

to about the middle of its stroke as well as the valve seat installed. This will allow for an easier installation.

Please see below for a more detailed and helpful way of installing the Turbosmart Gen V Anti lag valve.

MAINTENANCE

Turbosmart’s Gen V Anti lag valve will require periodic reapplication of spray grease such as Inox MX8 spray grease, this

is important that the manual override is used to move the valve up and down allowing the grease to be applied throughout

the entire valve gearbox. Turbosmart recommends that this is done regularly at least half yearly or in demanding

temperature environments.

It is also important to check V Band tightness after the Anti lag valve has run through a couple of heat cycles. To ensure

that the Anti lag valve is seated and sealing correctly.

TEMPERATURE

The Turbosmart Gen V Anti lag valve has a maximum thermal stress of 1250

o

C for 24hr if thermally cooled through the

water-cooling ports, it is important that the actuator internal housing

doesn’t go above a temperature of 150

o

C as this may

cause damage to the internal electronics. Turbosmart recommends that the Anti lag valve is water cooled and paired with

good airflow over the body to help regulate temperature. Turbosmart also recommends data logging the temperature that

is seen inside the actuator using the temperature sensor included onboard.

It is recommended that water cooling is in line with the turbo this will increase the longevity of the Anti-lag valve and allow

it to operate seamlessly. This does depend on the certain application and the rate and period at which the Anti lag valve is

exposed to the high temperatures.