Printed in the Federal Republic of Germany

TR-Electronic GmbH 2009, All Rights Reserved

04/23/2020

TR - ELA - BA - DGB - 0015 - 13

Page 67 of 92

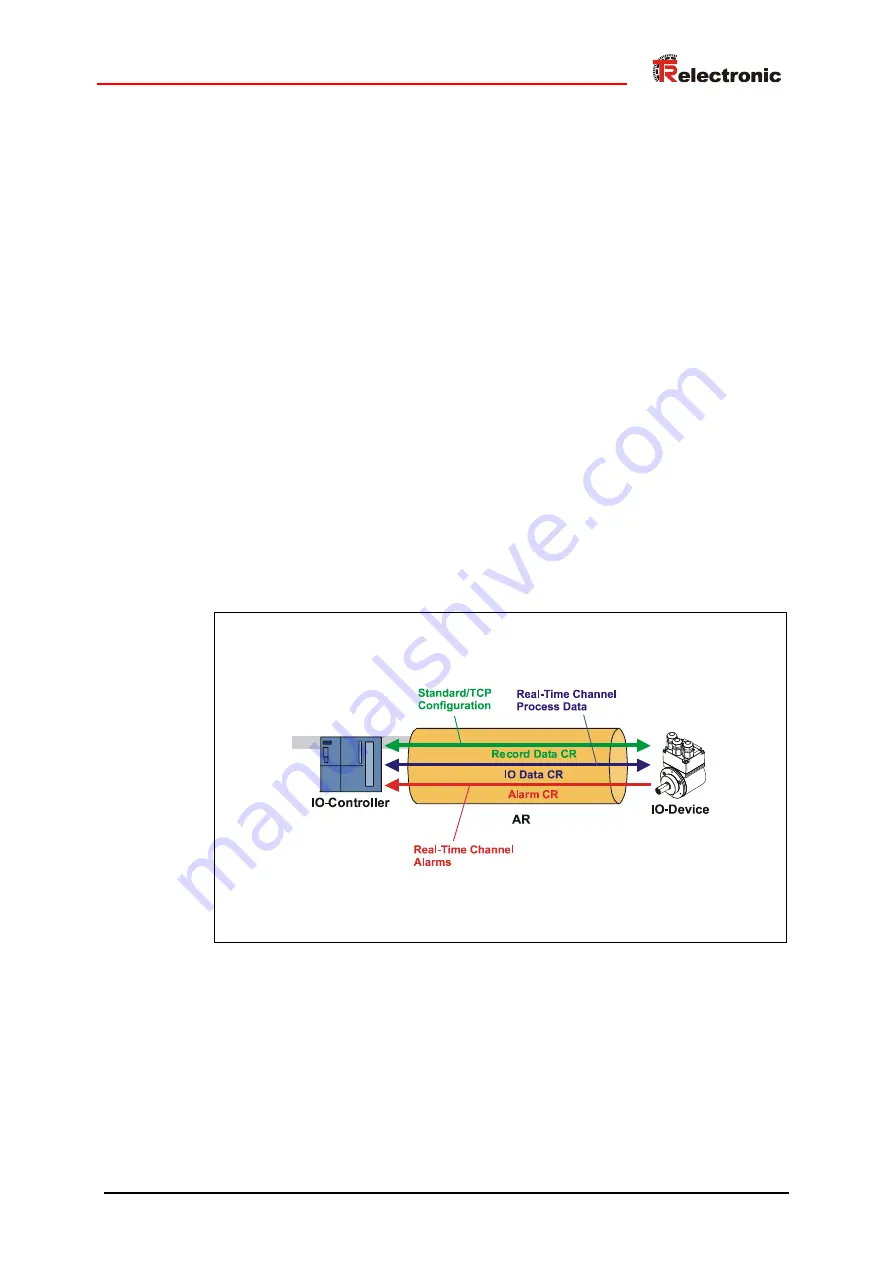

5.4 PROFINET IO Data exchange

PROFINET IO communication sequence:

According to his parameter setting, the IO-Controller establishes one or several

application relations to the IO-Devices. For this the IO-Controller is searching in the

network for parameterized names of the IO-Devices. Then the IO-Controller distributes

an IP-

Address to the located devices. In this case the service DCP “Discovery and

Control Program” is used. In the following start-up the IO-Controller transmits the

desired capabilities (modules/sub modules) and all parameters for the parameterized

IO-Devices. The cyclical IO-Data, alarms, acyclic services and multicast

communications are defined.

With PROFINET IO the transmission rate of the individual cyclic data can be adjusted

by a reduction factor. After the parameter setting the IO-Data of the IO-Device are

transferred according to unique request of the IO-Controller with a constant clock.

Cyclic data are not acknowledged. Alarms must be always acknowledged. Acyclic

data are acknowledged also.

For protection against parameterization errors the required capability and the actual

capability is compared in relation to the Device type, the Order-No. and the Input- and

Output data.

With

a successful system boot the IO-Devices start automatically with the data

transmission. In case of PROFINET IO a communication relation always follows the

provider consumer model. With cyclical transmission of the measuring value, the IO-Device

corresponds to the provider of the data, the IO-Controller (e.g. a PLC) corresponds to the

consumer. The transferred data always contains a status (good or bad).

Figure 6: Device communication

AR:

Application relation between IO-Controller and assigned IO-Devices

CR:

Communication relations for configuration, process data and alarms