36-EN

35-EN

– 18 –

EN

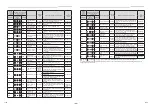

Group control

Simultaneous twin system

A combination with an outdoor unit allows simultaneous

ON / OFF operation of the indoor units. The following

system patterns are available.

- Two indoor units for the twin system

Twin system

Outdoor unit

Indoor unit

Indoor unit

Remote

controller

Finish of address setup by power-ON

y

For wiring procedure and wiring method, follow to the

“Electrical connection” in this manual.

y

When the power supply has been turned on, the

automatic address setup starts and which indicates

that address is being set up

fl

ashes on the display

part.

During setup of automatic address, the remote

controller operation is not accepted.

Required time up to the

fi

nish of automatic

addressing is approx. 5 minutes.

4

0

03

01

02

Electrical control box

Refrigerant

pipe

Drain

pipe

How to cancel louver lock

Set the wind direction to

“0000”

of the louver lock

setup procedure above.

0000

Setting data

y

When the setting is canceled, goes out.

Other operations are the same as those in

“How to set up louver lock (No swing)”.

To select horizontal wind

direction

The louver positions at cooling can be changed from

the smudge reducing position to the cold draftless

position.

Follow to the basic operation procedure

(

1

→

2

→

3

→

4

→

5

→

6

→

7

).

y

Specify

[45]

for the Code NO. in Procedure

4

.

y

Select the following data for the SET DATA in

Procedure

5

.

Wind

direction

SET DATA

Wind direction setting

0000

Smudge reducing position

(Air direction to reduce ceiling

contamination) [Factory default]

0002

Cold draft position

(Air direction to control cold air fall)

Remote controller sensor

The temperature sensor of the indoor unit senses

room temperature usually. Set the remote controller

sensor to sense the temperature around the remote

controller.

Select items following the basic operation procedure

(

1

→

2

→

3

→

4

→

5

→

6

→

7

).

y

Specify

[32]

for the Code No. in Procedure

4

.

y

Select the following data for the set data in

Procedure

5

.

Set data

Remote controller sensor

0000

Not in use (Factory default)

0001

In use

When

fl

ashes, the remote controller sensor is

defective.

Select the set data [0000] (not in use) or replace the

remote controller.

Communication type

When connecting to the central control device

dedicated to TCC-Link, it is necessary to change to

TCC-Link.

Follow to the basic opreration procedure

(

1

→

2

→

3

→

4

→

5

→

6

→

7

).

y

Specify

[FC]

for the Code No. in Procedure

4

.

y

Select the set data [0000] (TCC-Link) in Procedure

5

.

Set data

Communication type

0000

TCC-Link

0004

TU2C-Link (Factory default)

Fan speed setting when

thermostat-OFF in cooling

mode

Set the fan speed when the room temperature reaches

the set temperature in the cooling mode.

Follow to the basic opreration procedure

(

1

→

2

→

3

→

4

→

5

→

6

→

7

).

y

Specify

[9A]

for the Code No. in Procedure

4

.

y

Select the following data for the set data in

Procedure

5

.

Set data

Fan speed when thermostat-OFF

in cooling mode

0000

Remote controller setting

0001

Extremely low speed (UL)

(Factory default)

8°C operation

Pre-heating operation can be set for cold regions

where room temperature drops to below zero.

Follow to the basic opreration procedure

(

1

→

2

→

3

→

4

→

5

→

6

→

7

).

y

Specify

[d1]

for the Code No. in Procedure

4

.

y

Select the following data for the set data in

Procedure

5

.

Set data

8°C Operation setting

0000

None (Factory default)

0001

8°C Operation setting

Installing optional parts

When installing optional parts, data setup may be

required with remote controller.

Be sure to set the data, according to Installation

Manual for optional parts.

Information

The following functions require a connection with

the RBC-AMTU

½½½

and RBC-AMSU

½½½

remote

controller. For details, refer to the manual included with

the remote controller.

y

Individual unit selection during group operation

y

Individual setting of louver position (wind direction)

y

Swing type setting

y

Louver lock (no swing) setting

y

Energy saving operation (Power saving operation)

y

Noti

fi

cation of

fi

lter cleaning time

Others

The following functions can be used with this model.

Refer to the Service Manual for more information.

y

Rotation / backup operation

y

Free cooling

y

Secondary heating

y

Power shift