42-EN

41-EN

– 21 –

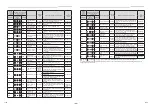

Monitoring function

This function can be used to call the service monitor

mode from the remote controller during a test run to

obtain the temperature of the sensors of the remote

controller, indoor unit, and outdoor unit.

2, 4

3

5

1

1, 2

4

Indoor unit

number

Data

“Monitoring function” display

1

Push and hold menu button for 10 seconds or

more. “Monitoring function” is displayed on a

screen.

2

Every pushing [

] [

] buttons, the indoor

unit numbers in group control are displayed

successively.

3

Push OFF timer button to con

fi

rm the selected

indoor unit.

4

Every pushing [

] [

] buttons, Code No. of

the item is changed successively.

5

After you have

fi

nished checking, push

“ON/OFF” button, return to normal mode.

Indoor unit data

Code No.

Data name

01

Room temperature (remote controller)

02

Indoor unit intake air temperature (TA)

03

Indoor unit heat exchanger (coil)

temperature (TCJ)

04

Indoor unit heat exchanger (coil)

temperature (TC)

07

Indoor unit fan speed (×1 rpm)

B9

Communication protocol

(0000: TCC-Link, 0001: TU2C-Link)

F3

Indoor unit fan cumulative operating hours

(×1 h)

F8

Indoor unit discharge air temperature *1

Outdoor unit data

*2

Code No.

Data name

60

Outdoor unit heat exchanger (coil)

temperature (TE)

61

Outside air temperature (TO)

62

Compressor discharge temperature (TD)

63

Compressor suction temperature (TS)

65

Heatsink temperature (THS)

6A

Operating current (×1/10)

6D

Outdoor heat exchange (coil)

temperature (TL)

F1

Compressor cumulative operating hours

(×100 h)

*1 : The above temperature values are estimated from the

temperature of the heat exchanger. It may differ from the

actual discharge temperature.

*2 : For outdoor unit data, refer to the Installation Manual and

Service Manual of the outdoor unit.

10

Maintenance

CAUTION

Before maintenance, be sure to turn off the leakage

breaker.

Cleaning of air

fi

lter

•

Clogging of the air

fi

lter reduce cooling / heating

performance.

Cleaning of panel and air

fi

lter

Preparation :

1. Turn off the air conditioner by the remote controller.

2. Open the air intake grille.

• Slide the button of the air intake grille inward, and

open the air intake grille slowly while holding it.

Air intake

grille

Knob

Cleaning of air

fi

lters

If the air

fi

lters are not cleaned, it not only reduce the

cooling a performance of air conditioner but causes

a failure in the air conditioner such as water falling in

drops.

Preparation :

1. Stop the operation by remote controller.

2. Dismount the air

fi

lter.

Strap to

prevent falling

Air

fi

lter

Use a vacuum cleaner to remove dust from

the

fi

lters or wash them with water.

•

After rinsing the air

fi

lters with water, dry them in the

shade.

•

Set the air

fi

lter into the air conditioner.

Clean the panel and air

fi

lter with water:

•

Wipe down the panel and air

fi

lter with a sponge or

towel moistened with a kitchen detergent. (Do not

use any metallic brush for cleaning.)

•

Carefully rinse the panel and air

fi

lter to wash out

the detergent.

•

After rinsing the panel and air

fi

lter with water,

dry it in the shade.

1. Close the air intake grille.

• Close the air intake grille, slide the knob outward,

and

fi

x the air intake grille securely.

Knob

Air intake

grille

2. Turn on the circuit breaker, then push the

button

on the remote controller to start operation.

CAUTION

•

Do not start the air conditioner while leaving the

panel and air

fi

lter removed.