–

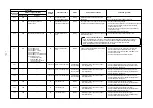

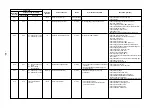

83

–

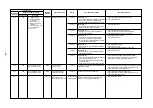

Check code

Main remote

controller

P13

P15

P17

P19

P20

Outdoor 7-segment display

Check code

P13

P15

P17

P19

P20

Sub-code

—

01: TS condition

02: TD condition

—

Detected outdoor unit

No.

—

Detected

position

I/F

I/F

I/F

I/F

I/F

I/F

Check code name

Outdoor liquid back

detection error

Gas leak detection

(TS1 condition)

Gas leak detection

(TD condition)

Discharge temp TD2 error

4-way valve operation error

High-pressure protective

operation

Status

All stop

All stop

All stop

All stop

All stop

All stop

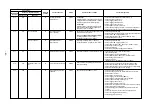

Error detection condition

<In cooling>

While the system is operating in COOL mode,

a high pressure value was detected in follower

unit in which compressor did not operate.

<In heating>

While the system is operating in HEAT mode,

outdoor PMV of which opening degree was

100p or less for a certain time.

Suction temp exceeded the judgment standard

temp for 10 minutes or more.

<TS error judgment standard temperature>

In cooling operation: 60°C or higher

In heating operation: 40°C or higher

Discharge temperature TD1 or TD2 was

continuously 108°C or higher for 10 minutes.

Discharge temperature (TD2) exceeded 115°C.

When abnormal refrigerating cycle data was

detected in heating

Pd sensor detected 3.6MPa or more.

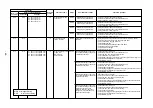

Check item (position)

• Check full close operation of outdoor PMV (1, 2).

• Check Pd and Ps sensor error.

• Check clogging of SV2 circuit.

• Check clogging of balance pipe.

• Check clogging of SV3B circuit.

• Check outdoor P.C. board (I/F) error.

• Check capillary clogging of oil return circuit from oil separator.

• Check leakage of check valve of the main discharge pipe.

• Check refrigerant shortage.

• Check full open of outdoor service valves (gas side, liquid side).

• Check outdoor PMV clogging (PMV1, 2).

• Check characteristics of TS1 sensor resistance value.

• Check leakage of SV4 circuit.

• Check refrigerant shortage.

• Check outdoor PMV clogging (PMV1, 2).

• Check characteristics of TD1, TD2 sensor resistance value.

• Check indoor air filter clogging.

• Check pipe clogging.

• Check SV4 circuit (Valve leakage, misinstallation)

• Check full opening of outdoor service valves

(gas side, liquid side).

• Check clogging of outdoor PMV (PMV1, 2).

• Check characteristics of TD2 sensor resistance value.

• Check leakage of SV42 circuit.

• Check SV4 circuit.

(Miscabling and misinstallation of SV41 and SV42)

• Check coil error and connector connection of 4-way valve.

• Check characteristics of TS1/TE1 sensor resistance value.

• Check characteristics of Pd, Ps pressure sensor output voltage.

• Check misconnection of TE1 and TL sensors.

• Check Pd pressure sensor error.

• Check full opening of service valves (Gas side, Liquid side).

• Check outdoor fan error.

• Check outdoor fan motor error.

• Check clogging of outdoor PMV. (PMV1,2)

• Check clogging of indoor/outdoor heat exchangers.

• Check air short-circuiting in outdoor unit.

• Check clogging of SV2 circuit.

• Check outdoor P.C. board (I/F) error.

• Check indoor fan system error. (Cause of air volume decrease)

• Check valve opening of indoor PMV.

• Check miscabling of communication line between indoor and

outdoor.

• Check operation error of check valve of discharge pipe.

• Check circuit of gas balance SV4 valve.

• Check refrigerant overcharge.