Figure 21

1.

Dipstick

2.

Dipstick tube

3.

Insert the dipstick fully into the dipstick tube, then

remove the dipstick (Figure 21).

4.

Read the oil level on the dipstick.

•

If the oil level is too low, slowly pour a small

amount of the specified oil into the oil-filler neck

(Figure 44), wait 3 minutes; refer to step 1 in Filling

the Engine with Oil (page 40).

•

If the oil level is too high, drain the excess oil until

you obtain the correct oil level on the dipstick;

refer to Draining the Engine Oil (page 39).

5.

Repeat steps 2 through 4 until the oil level is correct.

6.

Install the dipstick and oil-fill cap securely.

7.

Install the right-side panel; refer to Installing the Side

Panels (page 37).

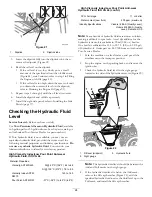

Checking the Hydraulic Fluid

Level

Service Interval:

Before each use or daily

Use

Toro Premium All-season Hydraulic Fluid

(available

in 5-gallon pails or 55-gallon drums. See the parts catalog or

an Authorized Toro Service Dealer for part numbers).

If Toro hydraulic fluid is not available, you may use an

equivalent hydraulic fluid, provided that it meets all the

following material properties and industry specifications.

Do

not use a synthetic hydraulic fluid.

Consult with your

lubricant distributor to identify a satisfactory product.

High Viscosity Index/Low Pour Point Anti-wear

Hydraulic Fluid, ISO VG 46

Material Properties:

St @ 40°C (104°F): 44 to 48

Viscosity, ASTM D445

St @ 100°C (212°F): 7.9 to 8.5

Viscosity Index ASTM

D2270

140 to 160

Pour Point, ASTM D97

-37°C (-34°F) to -45°C (-49°F)

High Viscosity Index/Low Pour Point Anti-wear

Hydraulic Fluid, ISO VG 46 (cont'd.)

FZG, Fail stage

11 or better

Water content (new fluid)

500 ppm (maximum)

Industry Specifications:

Vickers I-286-S (Quality Level),

Vickers M-2950-S (Quality

Level), Denison HF-0

Note:

Many brands of hydraulic fluids are almost colorless,

making it difficult to spot leaks. A red dye additive for the

hydraulic system oil is available in 20 ml (0.68 oz) bottles.

One bottle is sufficient for 15.1 to 22.7 L (4.0 to 6.0 US gal)

of hydraulic oil. Order part no. 44-2500 from an Authorized

Toro Service Dealer.

1.

Park the machine on a level surface, and put all the

attachments in the transport position.

2.

Stop the engine, set the parking brake, and remove the

ignition key.

3.

Check the hydraulic fluid level in the sight gauge

located at the side of the hydraulic reservoir (Figure 22).

Figure 22

1.

Fill level (midpoint)

3.

Hydraulic fluid

2.

Sight gauge

Note:

The hydraulic fluid level should be between the

Add and Full marks on the sight gauge.

4.

If the hydraulic fluid level is below the Add mark,

remove the fill cap/breather (Figure 22), add the

specified hydraulic fluid to raise the fluid level up to the

Full mark, and install the fill cap/breather.

24

Содержание RT600

Страница 71: ...Notes 71...