Maintenance

WARNING

Disconnect all power sources to the machine before

doing maintenance work.

Note:

Download a free copy of the schematics by visiting

www.Toro.com and searching for your machine from the

Manuals link on the home page.

Lubrication

Lubricating the machine

•

Use an automotive, all-purpose grease.

•

Lubricate regularly, after 25 hours of normal operation.

•

Lubricate daily when operating in extremely dusty and

dirty conditions.

•

Lubricate all bearings, bushings, and chains.

Lubrication Procedure

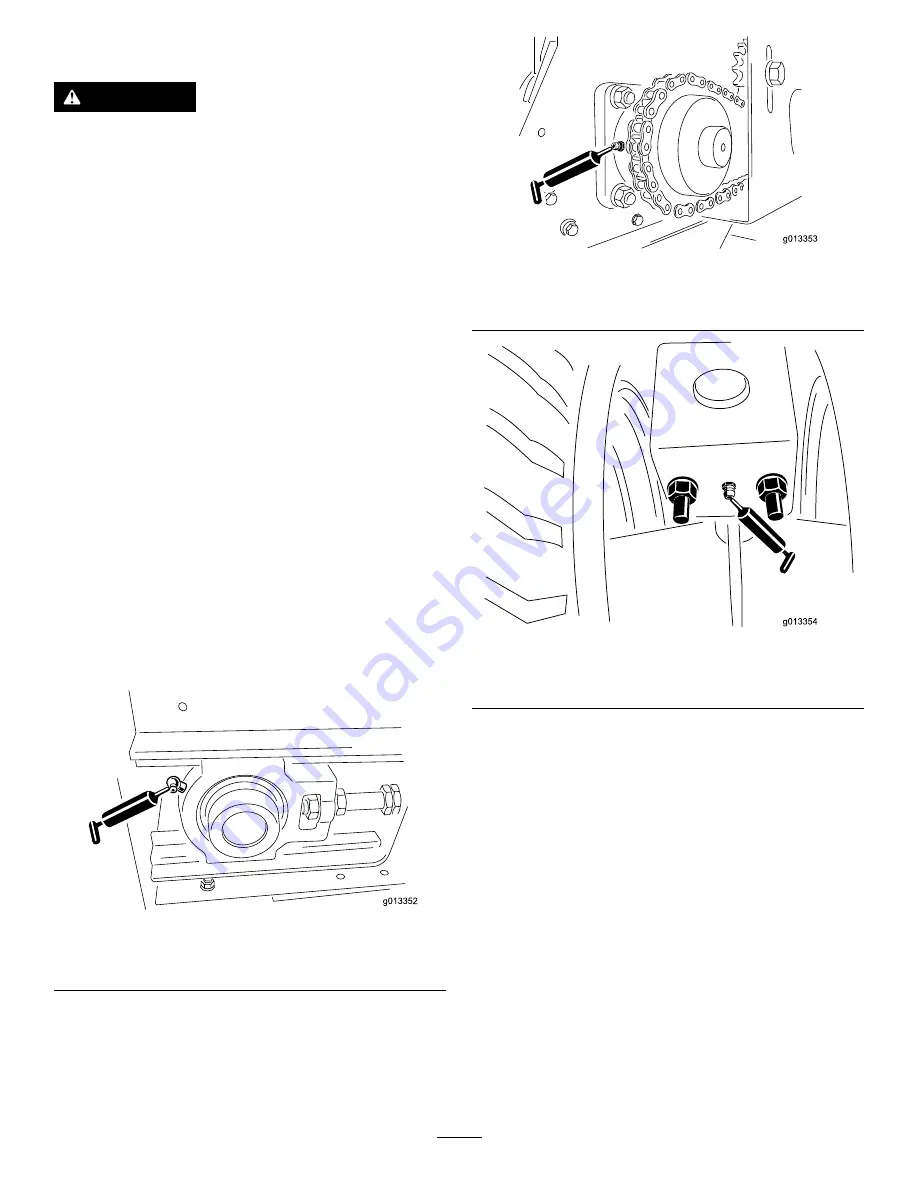

Several grease fittings are located on the machine and the

tow-behind chassis (

and

1.

Clean the grease fittings.

2.

Pump the grease into the bearings and the bushings.

3.

Clean off the excess grease.

4.

Clean and repack the wheel bearings every year or

every 300 hours of operation

Figure 52

1.

Grease fitting on Base Model (one at left front, one at right

front)

Figure 53

1.

Grease fitting on Base Model (one at left rear, one at right

rear)

Figure 54

1.

Grease fitting on tow-behind chassis (front and rear, left and

right). Grease once per year.

Daily Checks

At the start of each day, complete these safety checks before

operating the machine. Report any safety problems to your

supervisor. See the Safety Instructions in this manual for

details.

Tires and Wheels

•

The recommended tire pressure for the Tow Chassis is 10

psi (69 kPa), or as recommended by the tire manufacturer.

Refer to the Operator's Manual for the tow vehicle tire

specifications.

•

Check for excessive wear or visible damage.

•

Check that the wheel bolts are tight and none are missing.

Rear Gate

Check that the adjustable section of the rear gate opens and

closes without sticking.

34