27

4.

Remove the drain plug (Fig. 41).

m–7468

1

Figure 41

1. Oil drain plug

5.

When the oil has drained completely, replace the plug.

Note:

Dispose of the used oil at a certified recycling

center.

6.

Remove the dipstick and slowly pour oil into the filler

hole until the oil pours out of the filler hole.

m–7469

1

Figure 42

1. Dipstick

7.

Replace and secure the dipstick.

Servicing the Tracks

Check the tracks for excessive wear and clean them

periodically. If the tracks are worn, replace them. Check

the road wheels yearly.

Cleaning the Tracks

1.

With a bucket on the loader arm, lower the bucket to

the ground so that the front of the traction unit lifts off

of the ground a few inches.

2.

Stop the engine, and remove the key.

3.

Using a water hose or pressure washer, remove dirt

from each track system.

Important

Ensure that you use high-pressure water to

wash only the track area. Do not use a high-pressure

washer to clean the rest of the traction unit. High-pressure

washing can damage the electrical system and hydraulic

valves or deplete grease.

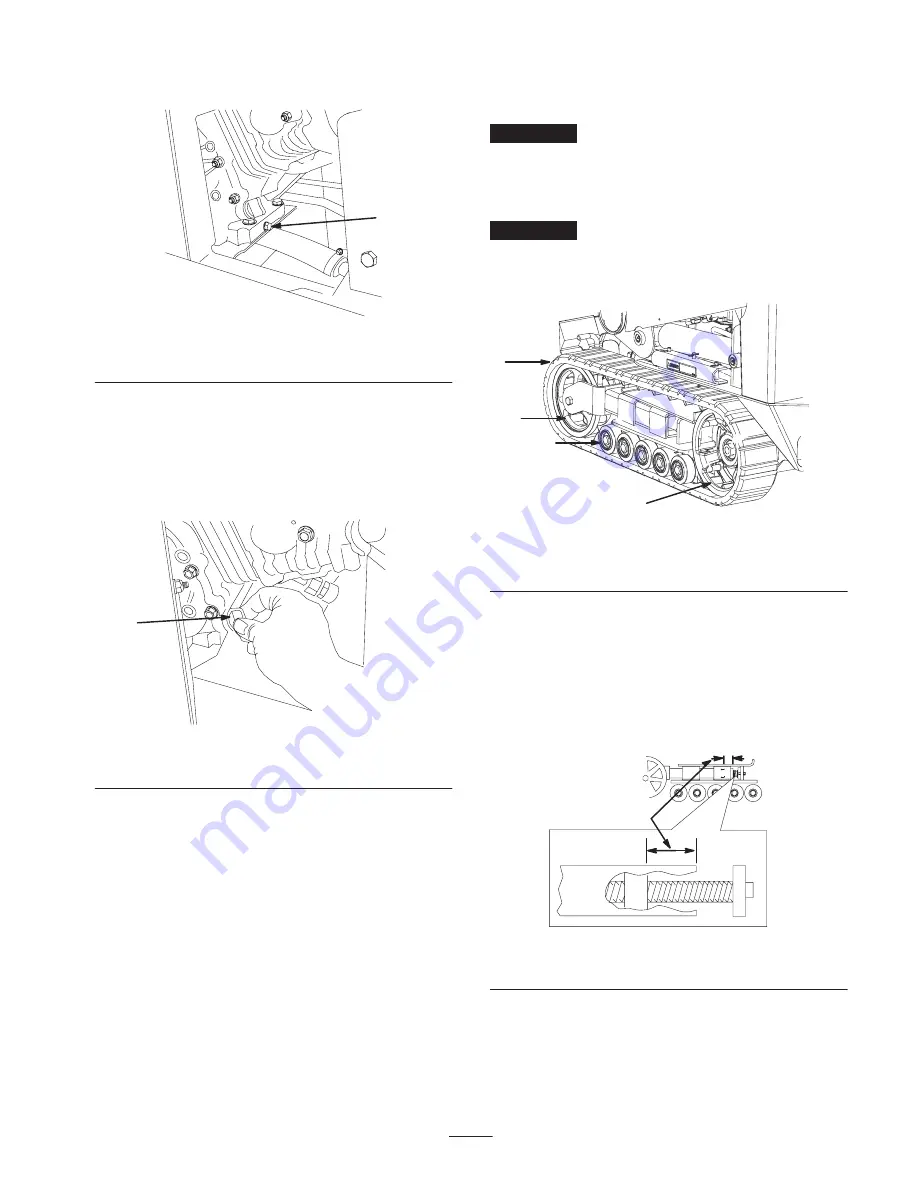

Important

Ensure that you fully clean the road

wheels, the tension wheel, and the drive sprocket

(Fig. 43). The road wheels should rotate freely when

clean.

1

2

3

4

m–7573

Figure 43

1. Track

2. Tension wheel

3. Road wheels

4. Drive Sprocket

Adjusting the Track Tension

Check and adjust the track tension every 100 operating

hours. There should be 2-3/4 inches (7 cm) between the

tension nut and the back of the tension tube (Fig. 44). If

not, adjust the track tension using the following

procedure:

m–4775

1

Figure 44

1. 2-3/4 inches (7 cm)

1.

Lower the loader arm, stop the engine, and remove the

key.

2.

Lift/support the side of the unit to be worked on so that

the track is off of the ground.

Содержание 22308

Страница 6: ...6 Slope Chart Note This page may be copied for personal use only M 4402...

Страница 37: ...37 Schematics Electrical Schematic...

Страница 38: ...38 Hydraulic Schematic...