Reel Drive Solenoid

g346523

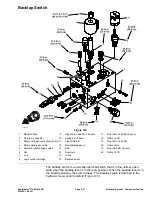

Figure 140

1.

Hydraulic manifold

2.

Solenoid

The hydraulic system on the Reelmaster uses a solenoid valve coil on the

hydraulic manifold (

). When the solenoid valve coil (SV) is energized,

hydraulic flow is directed to the cutting decks.

The standard control module provides current to the solenoid valve coil based

on the position of several inputs. A LED on the standard control module will be

illuminated when the solenoid valve coil is energized.

Testing

Note:

The solenoid does not have to be removed from the cartridge valve for

testing.

1. Make sure key switch is in the OFF position. Unplug wire harness electrical

connector from solenoid valve coil.

Note:

Prior to taking small resistance readings with a digital multimeter,

short the test leads together. The meter will display a small resistance value

(usually 0.5 ohms or less). This resistance is due to the internal resistance

of the meter and test leads. Subtract this value from the measured value

of the component you are testing.

2. Apply 12 VDC source directly to the solenoid. Listen for solenoid to switch on.

3. Remove 12 VDC source from the solenoid. Listen for solenoid to switch off.

4. Measure resistance between the two connector terminals. The resistance

should be about 7.2 ohms.

5. Install new solenoid if necessary.

A. Make sure O-ring is installed at each end of coil. Apply ”Loctite 242” or

equivalent to threads on end of valve stem before installing nut.

B. Tighten nut to a torque of

34 N·m (25 ft-lb)

. Over-tightening may damage

the solenoid or cause the valve to malfunction.

6. Reconnect electrical connector to the solenoid.

Electrical System: Component Testing

Page 6–40

Reelmaster

®

3100-D/3105-D

20252SL Rev A

Содержание 03200 Reelmaster 3100-D

Страница 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 88: ...g344528 Figure 28 Hydraulic System Hydraulic Schematic Page 5 12 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 89: ...g344526 Figure 29 Reelmaster 3100 D 3105 D Page 5 13 Hydraulic System Hydraulic Schematic 20252SL Rev A ...

Страница 198: ...g345756 Figure 95 Hydraulic System Service and Repairs Page 5 122 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 204: ...g345782 Figure 99 Hydraulic System Service and Repairs Page 5 128 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 308: ...Wheels Brakes and Chassis Service and Repairs Page 7 30 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 376: ...Universal Groomer Optional Service and Repairs Page 9 22 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 382: ...Page A 6 20252SL Rev A Reelmaster 3100 D 3105 D Drawing 122 1522 Rev A Sheet 1 of 1 Electrical Schematic g346835 ...

Страница 383: ...Reelmaster 3100 D 3105 D Drawing 122 1523 Rev B Sheet 1 of 2 20252SL Rev A Page A 7 Wire Harness Drawing CV g346834 ...

Страница 384: ...Page A 8 20252SL Rev A Reelmaster 3100 D 3105 D Drawing 122 1523 Rev A Sheet 2 of 2 Wire Harness Drawing g346833 ...

Страница 385: ......