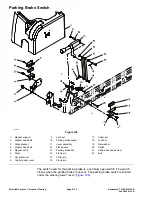

High Temperature Shutdown Switch

g342503

Figure 132

1.

Temp. shutdown switch

3.

Low oil press. switch

2.

Alternator

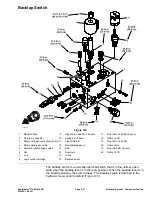

The high temperature shutdown switch (

) is attached to the water

pump housing on the engine and has a blue/white wire attached to it. This

switch is normally open and closes when engine coolant temperature reaches

approximately 110°C (230°F). The closed switch provides an input to the

Standard Control Module (SCM).

This input causes the SCM high temperature shutdown LED to illuminate and

the cutting deck to shut down. The high temperature shutdown switch and

circuit wiring should be tested as a SCM input before performing the following

testing procedure.

Testing

1. Park the machine on a level surface, lower the cutting deck, shut off the

engine, set the parking brake, and remove the key from the key switch.

2. Unlatch the hood and raise it.

DANGER

If the radiator or engine is hot, pressurized hot coolant can escape

and cause burns.

Do not open the radiator cap or drain the radiator when the coolant

is hot. Ensure that the engine is cool before removing the high

temperature shutdown switch from the engine.

3. Lower the coolant level in the engine.

4. Remove the wire harness connector from the high temperature shutdown

switch, and remove the switch from the engine.

Reelmaster

®

3100-D/3105-D

Page 6–31

Electrical System: Component Testing

20252SL Rev A

Содержание 03200 Reelmaster 3100-D

Страница 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 88: ...g344528 Figure 28 Hydraulic System Hydraulic Schematic Page 5 12 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 89: ...g344526 Figure 29 Reelmaster 3100 D 3105 D Page 5 13 Hydraulic System Hydraulic Schematic 20252SL Rev A ...

Страница 198: ...g345756 Figure 95 Hydraulic System Service and Repairs Page 5 122 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 204: ...g345782 Figure 99 Hydraulic System Service and Repairs Page 5 128 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 308: ...Wheels Brakes and Chassis Service and Repairs Page 7 30 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 376: ...Universal Groomer Optional Service and Repairs Page 9 22 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Страница 382: ...Page A 6 20252SL Rev A Reelmaster 3100 D 3105 D Drawing 122 1522 Rev A Sheet 1 of 1 Electrical Schematic g346835 ...

Страница 383: ...Reelmaster 3100 D 3105 D Drawing 122 1523 Rev B Sheet 1 of 2 20252SL Rev A Page A 7 Wire Harness Drawing CV g346834 ...

Страница 384: ...Page A 8 20252SL Rev A Reelmaster 3100 D 3105 D Drawing 122 1523 Rev A Sheet 2 of 2 Wire Harness Drawing g346833 ...

Страница 385: ......