BUILD THE DORSAL FIN

❏

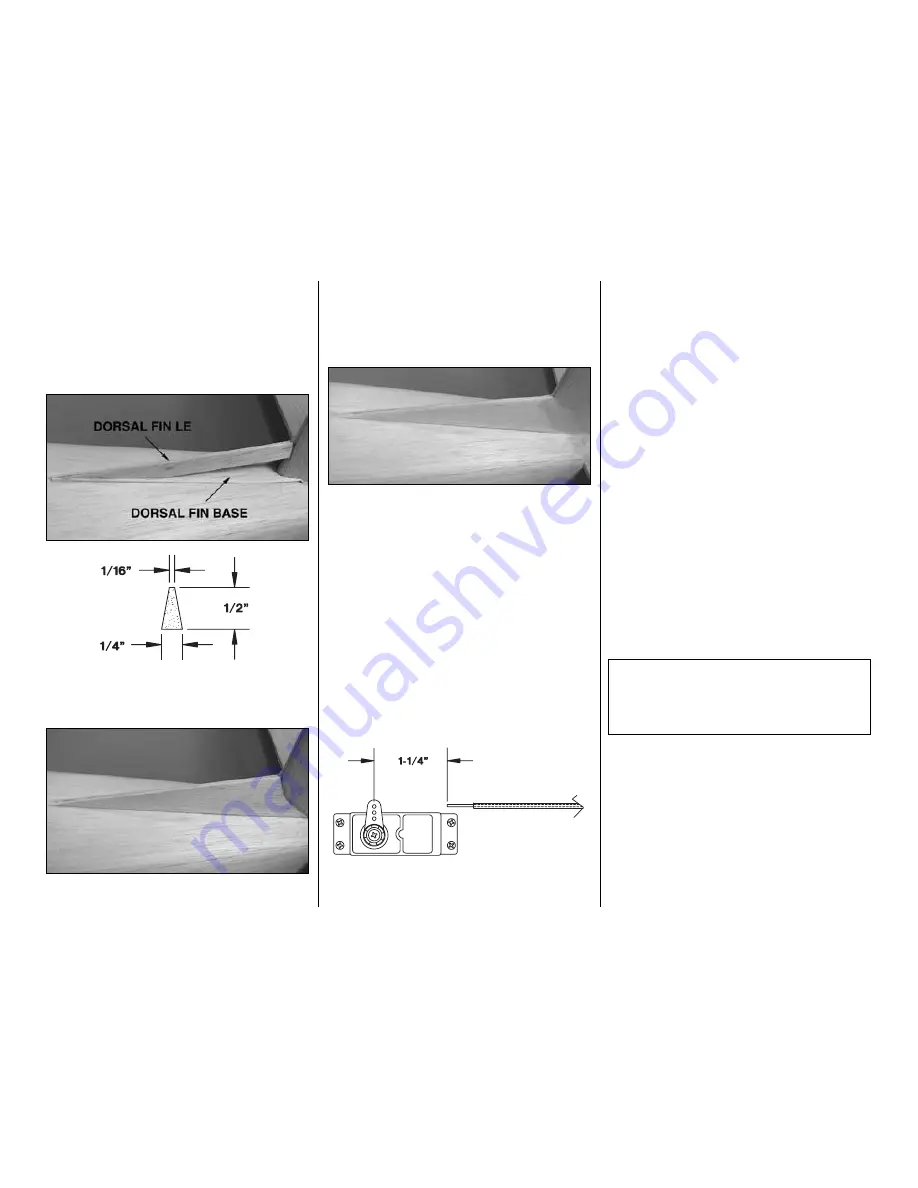

1. Use the pattern on the plan to make the

dorsal

fin base

from leftover 1/16” [1.6mm] balsa. Glue the

dorsal fin base to the top of the turtle deck. Make

sure the front of the base is

centered

on the fuse

centerline.

❏

2. Cut the 15” [381mm] tapered balsa

dorsal fin

LE

to the shape shown on the plan. Glue the dorsal

fin LE to the fin LE and the dorsal fin base.

❏

3. Make two

dorsal fin sheets

from leftover 1/16”

[1.6mm] balsa sheeting using the pattern on the

plan. Test fit and glue one of the sheets to the turtle

deck and dorsal fin base. Wet the sheet and glue it to

the dorsal fin LE. Make sure you do not pull the

dorsal fin LE off to one side when you glue the sheet

to it. Glue the other dorsal fin sheet in position.

❏

4. Apply Hobbylite

™

filler to the dorsal fin and fin

filler sheet to blend them to the fin. Apply filler to the

front of the dorsal fin to complete the taper and blend

it to the turtle deck. Do not apply all the filler in one

application but build up thin layers, allowing each

layer to fully dry before you apply the next. Sand the

filler, blending the dorsal fin, fin filler and fin into one

smooth contour.

HOOK UP THE RUDDER AND ELEVATOR

❏

1. Install the pushrods in the guide tubes.

Temporarily connect the clevis, with a silicone

retainer, to the elevator control horn and fit the

rudder and elevator in place.

❏

2. Place a servo arm on your rudder and elevator

servos. With the servos centered and the rudder and

elevators neutral, use a felt-tip pen to mark the

pushrods exactly 1-1/4” [31.8mm] from the holes in

the servo arms. Remove the pushrods from the

fuselage (see the note below). Cut them at the marks

you made.

Note: It is very difficult to remove the rudder pushrod

now that the stab is glued in place. It is not difficult to

solder the pushrod with it installed in the fuselage in

the following step. You might also consider cutting an

access hatch in the fuselage side so that you can

remove the pushrod. This hatch can also be used for

future maintenance.

❏

3. Silver solder a

threaded coupler

onto each wire

pushrod. Reinsert the pushrods into the fuselage and

thread a nylon clevis onto the couplers. Temporarily

connect the pushrods to the servos and rudder and

elevator. Adjust the length of the pushrods if necessary

by turning the clevises in or out.

Hint:

It will be easier to thread the clevis onto the

threaded coupler if you install it on the servo arm

first, using the arm for better leverage. Be careful not

to damage the pin on the clevis.

T-34B Fact:

Beech built a total of 423 T-34B

aircraft, starting in 1954. The Navy used the

aircraft for over twenty years, flying over 100,000

hours per year. Training was conducted at NAS

Saufley Field and NAS Whiting Field.

-43-

Содержание T-34B MENTOR

Страница 7: ...7 DIE CUT PATTERNS...