❏ ❏

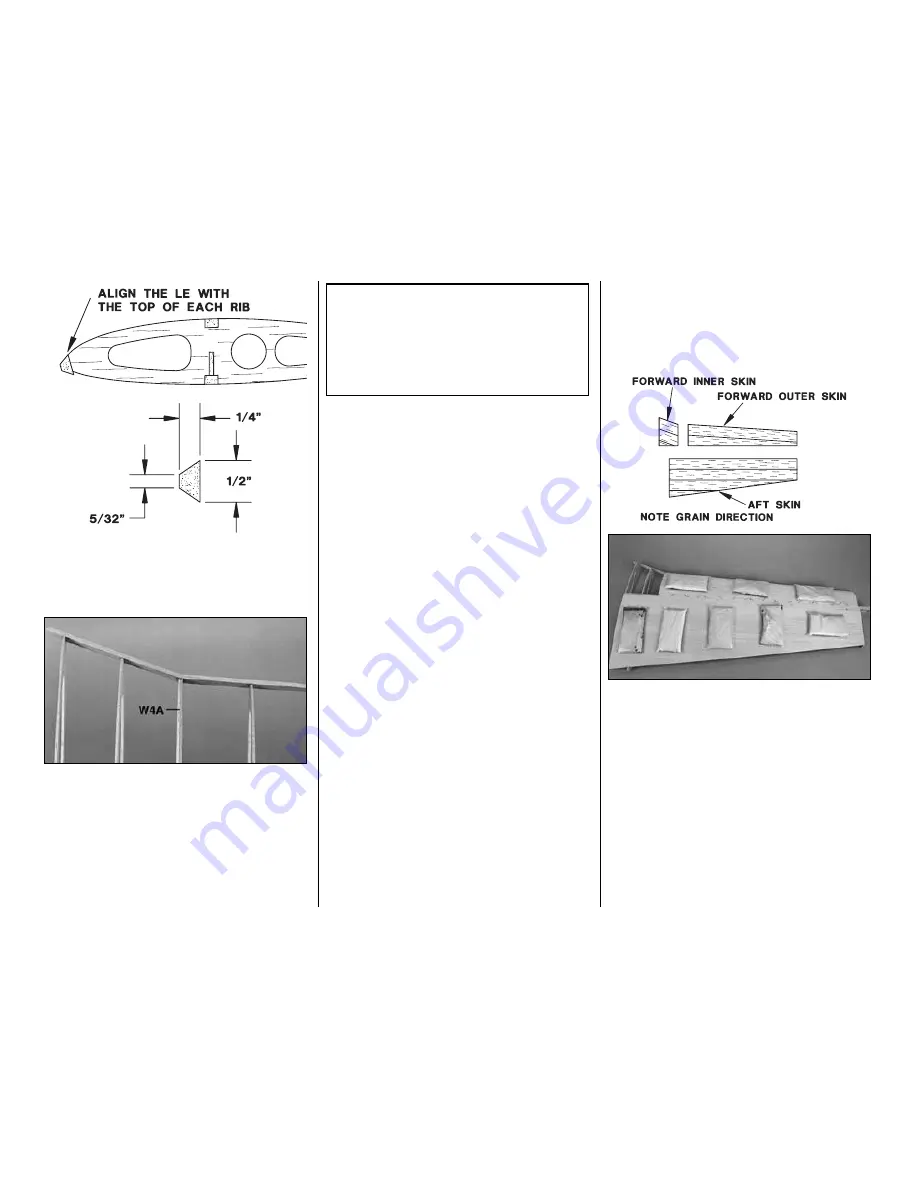

11. Cut a 1/4” x 36” [6.4 x 914mm] shaped

balsa

leading edge

to a length of 29-1/2” [749mm].

Glue the LE to ribs W4 through W14 so the top aligns

with the tops of the ribs (the same as on the stab).

❏ ❏

12. Bevel the end of the remaining piece of 6-1/2”

[165mm] leading edge so it matches the LE on the wing

when you position it on ribs W4, W3 and W2. Glue it in

position. Glue

rib W4A

to the side of rib W4.

Hint:

Glue

the LE to rib W2

last so you can use the dihedral gauge

to make sure W2 is at the correct angle.

Note:

Use a long straightedge along the length of

W2 to insure that it is flat along it’s length (from the

LE to the TE).

SHEET THE TOP OF THE WING PANELS

❏ ❏

1. Use a large sanding block or a bar sander

with 150-grit sandpaper to sand the tops of the top

spar, aft spars, LE and ribs so they all smoothly

blend together. Make sure the tops of the aft spars

match the tapering angle of the ribs but sand the ribs

lightly so you maintain the designed airfoil shape.

❏ ❏

2. Remove the T-pins from the bottom spar and

replace them so they are all sticking in from the front.

This way you will be able to remove them when the

aft top sheet is in position. Remove the T-pins from

the aft jig tabs and replace them in every other jig tab

so they all go into the building board at the same

angle (

you know the drill). Remove the weights from

the top of the wing (if you used them).

Note:

If you observe that the wing panel remains flat

and all the jig tabs are contacting your building board

when you remove the T-pins, you may leave the

T-pins out of the jig tabs. In this case the weights that

will be used to hold the sheeting to the ribs will be

enough to hold the wing flat to your building board.

Use this photo and the sketch for the next few

steps

. This photo shows a few weights on top of the

wing, but in actuality we used enough weights to fully

cover the skins. You can use magazines for weights

too. T-pins in the front ensure that the skins are

securely bonded to the top spar.

❏ ❏

3. Trim the aft wing skin so it fits the wing. The

TE

should be straight and true and contact the

stopper

portion of the jig tabs on ribs W14 and W3. The

front

of

the sheet should

end in the center of the top spar. The

ends should extend past W2 and W14 equally.

❏ ❏

4. Use your favorite method to glue the

aft

wing

skin to the wing. We recommend using aliphatic resin

because it gives you plenty of time to align the skin

and position your weights or T-pins. Hold the wing

skin in position with magazines or weights made

from plastic bags filled with lead shot or BBs. If you

choose to use T-pins to hold the skin to the wing,

lightly

mark lines on the top of the wing skin

indicating the location of the ribs underneath.

Do not

disturb the wing until the glue fully cures.

Beech Fact:

In 1952 the USAF ordered the YT-34

into production under the designation T-34A

Mentor. Beechcraft built a total of 353 T-34

Mentors for the USAF. [An additional 100 were

built for the USAF in Canada, as well as 25 for the

Canadian Air Force.] The T-34A was in production

from 1953 to 1956.

-21-

Содержание T-34B MENTOR

Страница 7: ...7 DIE CUT PATTERNS...