❏ ❏

5. Use 30-minute epoxy to glue the servo

mount blocks, with the servo attached, to the servo

hatch covers as shown on the plan. Roughen the

hatches with sandpaper where the blocks will be

glued so the glue will adhere better.

Note:

You can increase the strength of this joint by

drilling a few shallow 1/16” [1.6mm] holes into the

servo mount blocks. This will create epoxy pins that

extend into the blocks.

❏ ❏

6. Drill a 1/16” [1.6mm] hole through the hatch

covers into each servo mount block. Countersink the

holes and install a #2 x 3/8” [9.5mm] flat head sheet

metal screw. Test fit the servo hatches in the wing

and screw them down with the hatch cover screws.

❏

7. Return to the first step and mount the flap and

aileron servos in the other wing panel.

JOIN THE WING PANELS

❏

1. Remove the flaps. Test fit both outer panels to the

center section. Make small adjustments if necessary to

minimize any gaps you see.

Test fit your clamps to

make sure you have enough of them and to make sure

you know where you are going to place the clamps

when you actually glue the wing together.

❏

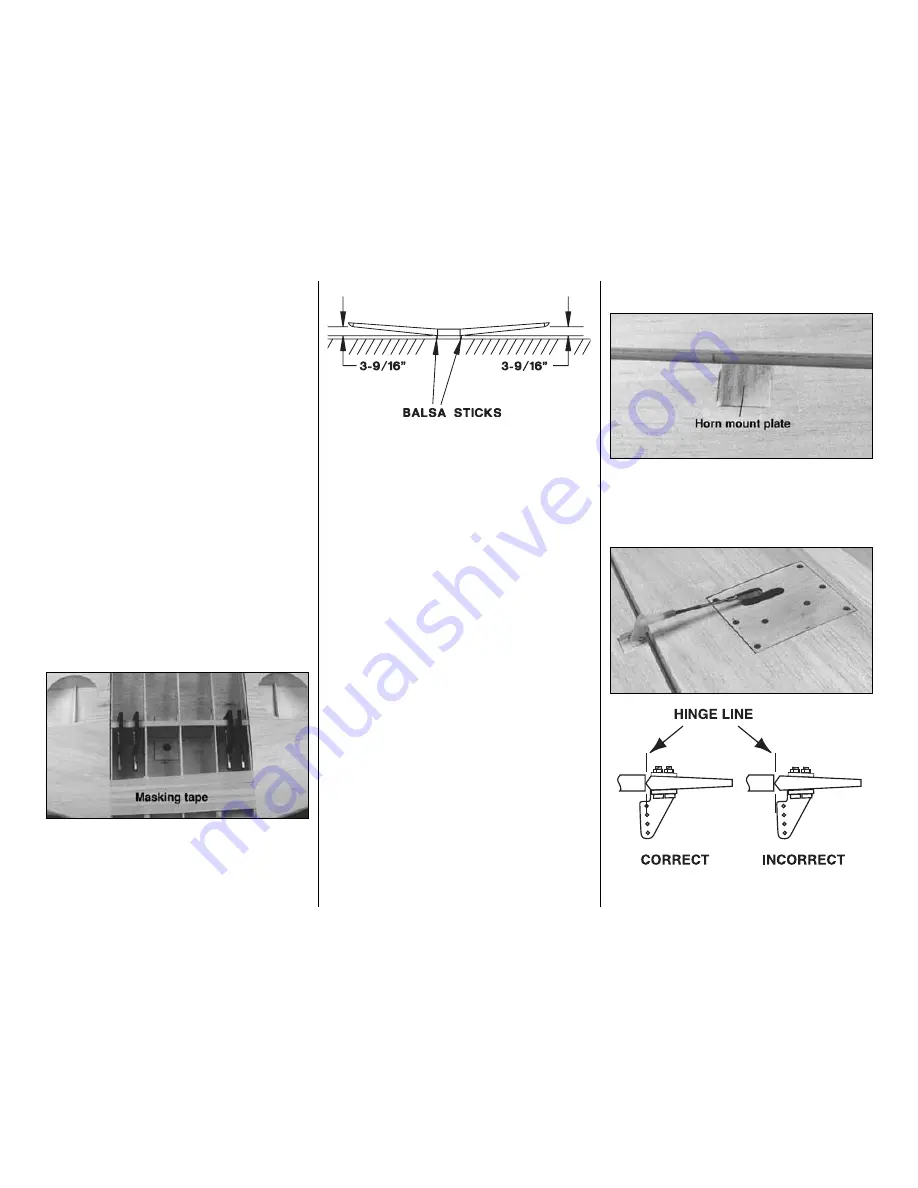

2.

Optional:

The dihedral braces and the

preset

angle of the root ribs on the outer panels will

determine the dihedral in the wing. But if you wish to

check the dihedral before you permanently glue the

wings together, clamp the wing together, raise the

center section off your workbench with balsa sticks

of equal size (so the wing is not resting on the

clamps) and measure the height of both wing tips.

The height of

both

tips (measured under the bottom

of the spar at tip rib W14) should be 3-9/16”

[90.5mm] (not including the balsa sticks). If the

measured dihedral of both wing tips is within a range

of 3-3/8” to 3-3/4” [85.7 to 95.3mm], the dihedral is

okay. It is important that both sides are the same.

Make adjustments as needed.

❏

3. Mix a batch of 45 or 30-minute epoxy to join the

wing panels to the center section. Apply epoxy to all

the mating surfaces of the end ribs, spars, and

dihedral braces. If you have installed the wires for the

wing tip lighting, pull the wires through the root ribs

so you can route them into the center section. Join

the outer panels to the center section and position

your clamps. Wipe away excess epoxy with a paper

towel before it cures and do not disturb the wing until

the epoxy cures.

MAKE THE FLAP & AILERON PUSHRODS

❏ ❏

1. Cut a 1/8” [3.2mm] deep notch in the aileron

for the die-cut 1/8” [3.2mm] plywood

aileron horn

mounting plate

where shown on the plan. Glue the

horn mounting plate to the aileron and sand it to

match the leading edge.

❏ ❏

2. Make the aileron pushrods from a .074” x 4” [1.9

x 101.6mm]

threaded one end rod

with a

nylon clevis

-33-

Содержание T-34B MENTOR

Страница 7: ...7 DIE CUT PATTERNS...